THE SCIENCE OF CRAFT BEER

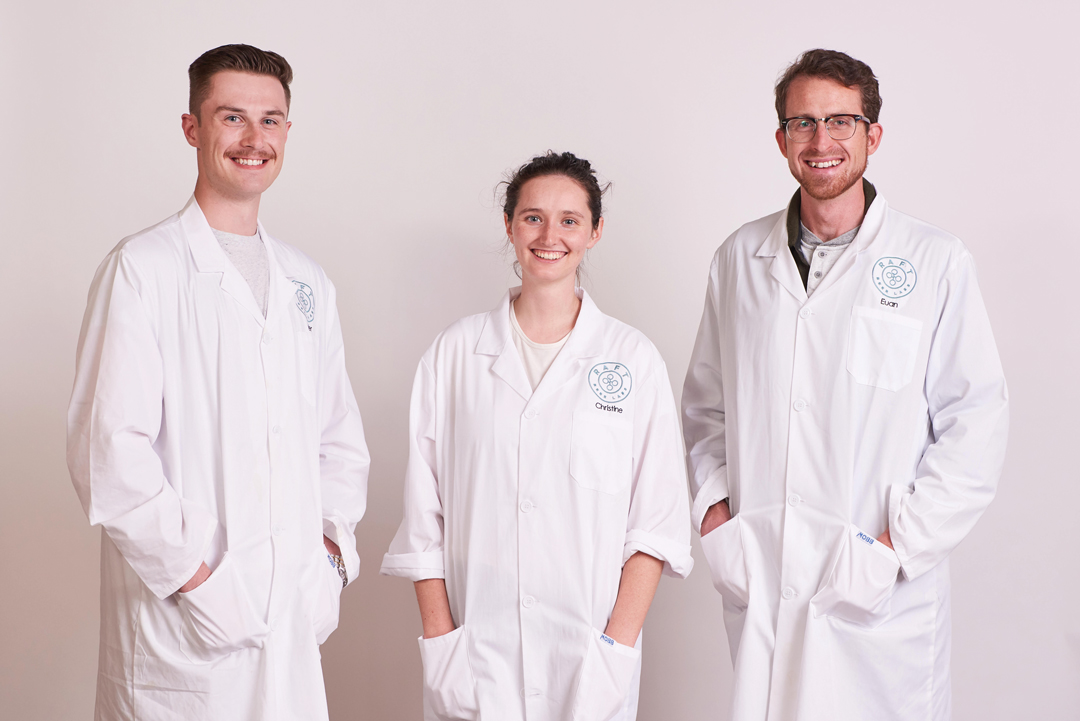

BY JENNIFER BARBER • PHOTO COURTESY OF RAFT BREW LABS: LEFT TO RIGHT, PETER RYNSBURGER, CHRISTINE DAWSON, EUAN THOMSON

Craft brewers produce premium beer on a small but spirited scale, though often can’t maintain in-house laboratories to manage quality control. Calgary’s Raft Brew Labs, comprised of a small team of chemists and microbiologists, provides the scientific analysis brewers need to ensure their end-products are safe and consistent.

“We provide custom lab services so what is being brewed is exactly up to target specifications,” said founder and microbiologist Euan Thomson. With a business model that reflects the scrappy nature of the craft beer industry, the lab was established without a large capital investment. Raft utilizes the state-of-the-art facilities of the Innovate Calgary shared lab space located at the University of Calgary. Here, the team can work in collaboration with a greater network of scientists as needed.

“We try to be really quick, really responsive as if we were an in-house lab,” said Thomson. “Our goal is to provide that big brewery science for small breweries.” His team collects samples at all stages of the brewing process from fermentation to packaged product. These are tested for the presence of bacteria and wild yeast, colour consistency, pH level, hops performance, alcohol level and other quality parameters that include taste.

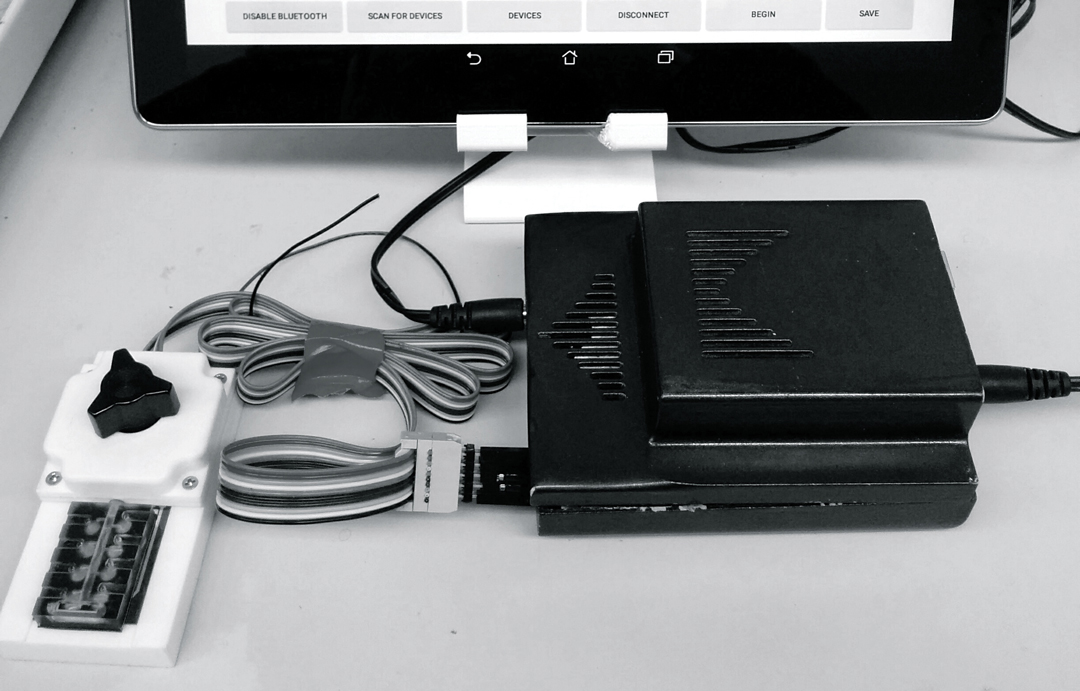

While using standard petri dish cultures, Raft also employs high-tech DNA analysis tools to identify microbial troublemakers. “Just a few bacterial groups can spoil a batch of beer, but a range of wild yeasts can also cause problems,” said Thomson. “Whether that is a serious safety issue or even just the flavour, brewers typically don’t want bacteria or wild yeasts in their beer.”

Raft Brew Labs also checks free amino nitrogen (FAN) levels. FAN content is an indicator of malt performance. “When we have a poor barley growing year like 2021, the performance of the malt could be a big issue,” said Thomson. “This year is going to be a big year to make sure brewers measure the performance of the barley in their end-product.”

“We all have a huge affinity for the craft beer scene,” said Thomson. “We’re all recovering or current homebrewers, and several of us have worked at breweries. We pay close attention to current trends in the industry, which helps us provide tailored scientific recommendations for our clients as new trends emerge.” Reflective of the craft brewing industry’s strong community engagement, Raft created the EACH+EVERY: Businesses for Harm Reduction collective. The group supports the reduction of drug poisoning deaths. For these efforts, it recently earned a community support award from the Alberta Small Brewers Association.

Expense and lack of expertise limit the testing capacity of craft brewers. Andrew Bullied of Calgary’s Annex Ale Project said the only way to establish consistency within a brewer’s products is to know what’s in them. “In order to push the needle forward we are always experimenting, but our customers who want our four core products want it to taste the same every time. Raft provides us with the quantitative data that combine with our qualitative data for consistent performance. Raft also tracks down and analyzes spoiler organisms before they become a problem.”

Thomson’s next ambition is to create a database to track the chemical and microbiological parameters Raft measures for its clients. This would eventually give craft brewers better knowledge of where the quality of their products is situated within the industry.

“This sort of benchmarking is really helpful for market comparisons, for example, but is basically inaccessible for small companies,” said Thomson. “We want Raft Brew Labs to be the go-to knowledge bank so brewers can stay ahead of their problems to create a consistent product for consumers.”

Comments