ROLL WITH THE PUNCHES

BY PETER WATTS • PHOTO BY ANTHONY HOULE PHOTOGRAPHY

The net result of combined low carry-in stocks, the severe drought of 2021 and record high prices for feed barley has been a supply crunch that has made it difficult for North American maltsters to source sufficient supplies. The available barley generally has quality challenges that include very high protein content and reduced germination caused by 2021 weather conditions. We now have greater perspective on how the malting and brewing industries are dealing with the challenges associated with the less-than-optimal crop.

This year more than ever, maltsters must carefully consider the quality parameters of their barley supply. This includes protein content, percentage of kernels with pre-sprout damage and size distribution. As high-protein barley typically takes longer to absorb moisture, maltsters must closely monitor its water absorption during steeping, the first stage of malting. The barley is submerged for 24 to 36 hours with one or two dry rest periods during this time. Longer submersions followed by longer dry rests may be required. Conversely, barley with pre-harvest germination tends to uptake water more quickly, so maltsters must avoid “drowning” those water-sensitive kernels.

During germination, components of the barley kernel such as starches and proteins are broken down so as to be made usable in the brewing process. High-protein barley is associated with high beta-glucan content in finished malt. This fibre found in the barley cell wall becomes gummy during brewing, which can impede straining and filtration processes. Maltsters must ensure malt has been sufficiently modified to keep beta-glucan levels down. Protein and high moisture content can also produce excessive soluble protein, high free amino nitrogen (FAN) and can diminish extract yield, which is the rate starches convert to sugars.

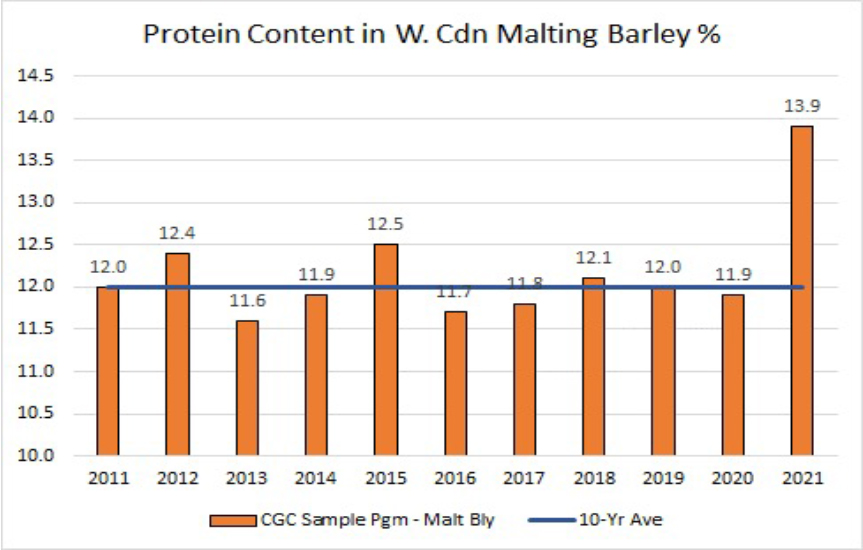

Average protein content in 2021 western Canadian malting barley is 16 per cent higher than the 10-year average. Source: Canadian Grain Commission Harvest Sample Program.

The last stage of the malting process, kilning may need to be conducted at lower temperatures for longer periods to avoid undesirably dark malt colour caused by high soluble protein content.

Ultimately, the 2021 malting barley crop requires malt processors to dedicate more attention, resources and processing time than is typical. Assuming the maltster does their job, many of the desired brewer specifications will be met, however, high protein content is unavoidable. It can result in lower extract levels as less starch equals less sugar available for fermentation. Increased beta-glucan content can cause production problems while high FAN content can cause fermentation difficulties and impact flavour.

To offset lower extract, brewers can increase the overall malt bill (use a higher malt-to-water ratio), although this increases costs. Additional process adjustments can be made to maximize extract when kernel plumpness is low.

If the malt Certificate of Analysis indicates high beta-glucan, brewers may introduce a protein rest that allows the beta-glucanase enzyme to break down the beta-glucan material. Brewers can also add beta-glucan enzymes at a later stage to similar effect.

Another potential challenge for brewers working with high-protein malt is the associated high enzyme content. Enzymes convert starches to sugars, but high enzyme content can cause very rapid conversion and the production of insufficient residual sugars. The result can be thin beer with little body and higher than intended alcohol content.

Maltsters and brewers are adapting to the atypical 2021 malting barley crop to produce the best quality malt and beer possible. Extraordinarily challenging, the extra production steps it has generated require time and resources. But with determined effort, beer drinkers will continue to enjoy the quality brews they expect.

Peter Watts is the CMBTC managing director.

Comments