NEGATIVE NUMBERS

BY PETER WATTS

The drought of 2021 affected crops across the Canadian Prairies and the Great Plains of the U.S. This significantly impacted crop yield and quality in the major barley producing provinces in Western Canada and the states of North Dakota, Idaho and Montana. To add insult to injury, many farms finally received precipitation in the middle of harvest. The hot, dry growing season produced very high protein content while the late moisture triggered significant pre-harvest sprouting.

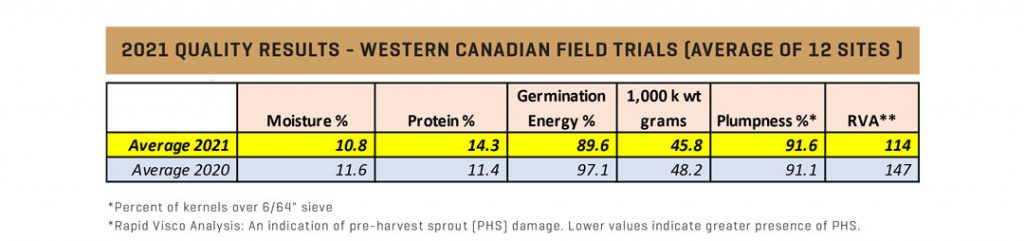

The malting industry generally looks for protein content between 10 and 12.5 per cent. Current protein levels are virtually unprecedented, averaging just above 14 per cent. Heterogeneity (unevenness) of kernel size is generally higher than average and test weight is lower than last year. Germination energy is often below the industry minimum standard of 95 per cent. There are two bright spots in an otherwise dismal quality profile: water sensitivity is low, which is positive, and the percentage of plump kernels is surprisingly higher than the 2020 average.

This implies new drought-tolerant varieties and modern production practices mitigated the drought’s impact. Nonetheless, the drought has diminished the supply of malting barley available to North American maltsters and the quality of available grain would not normally be considered selectable.

The table below shows the results of barley quality evaluation in western Canadian field trials.

The quality profile of the 2021 barley crop will present significant processing challenges for maltsters and brewers in the coming year and will demand a balancing act from both.

High protein content is inversely related to extract levels. This means less sugar is available from the finished malt for fermentation, which forces brewers to use more malt per unit of beer produced. High protein also causes high beta-glucan levels in malt. A soluble fibre in the kernel cell wall, too much beta-glucan can cause problems in more than one stage of brewing. High protein levels in barley can also produce too much soluble protein, which can cause problems with the flavour and colour of the finished beer. Excessive levels of free amino nitrogen, a byproduct of protein solubilization, can be an issue for brewers of all sizes. In finished malt it can lead to diminished shelf life and create haze in beer.

The high protein content and variable kernel size typical of the 2021 crop can cause uneven water uptake during steeping, the first stage of malting. Water uptake in the malting process is also affected when barley has undergone pre-harvest sprouting, as much of it has in 2021. High protein content can also create a cascade of problems throughout the brewing process.

Large brewers will be able to accommodate the year’s challenging malt quality. For example, they may increase the ratio of adjuncts (corn, rice) to offset the high protein level of the malt and compensate for lower extract. They will, however, potentially face difficulty controlling beer flavour and colour. Craft (all malt) brewers may have greater difficulties because they have less flexibility. As they typically work with malt protein levels of 10 to 11.5 per cent, working with proteins of 13 to 14 per cent will inevitably create processing headaches.

It has been a challenging year for barley farmers and the North American malting and brewing industry now finds itself in uncharted quality territory. As they say, necessity is the mother of invention and in the next issue of GrainsWest, we will discuss how the industry is adapting to this year’s challenges.

Peter Watts is the CMBTC managing director.

Comments