HAMMER TIME

BY JENNIFER BARBER • PHOTOS BY ANTHONY HOULE PHOTOGRAPHY

Farmer Keith Woynorowski built the Hammer Malt facility and the entire malting system from scratch. He processes the farm’s own malting barley within silver, cylindrical dairy tanks repurposed as combination kilns and germination vessels. The malt is transported from one stage of processing to the next through pneumatic tubes and the entire system is computer automated. Far from being cobbled-together in appearance, the rig looks something like a homey space station.

On his family’s 3,000-acre farm near Westlock, Keith grows canola, wheat and oats as well as feed and malting barley with his father Mick and brother JD. With help from his wife and business partner Jennifer, he established Hammer as a value-added project that taps the family’s barley growing expertise. The business now produces specialty malts for Alberta’s craft distillers and brewers.

The maltster’s namesake tool, which is mounted on the malthouse wall, is the perfect symbol for the do-it-yourself spirit of the farm and its offshoot barley business. An ancient claw hammer, with a replacement handle made of a length of hockey stick wrapped in tape, it once belonged to Keith’s late grandfather Walter, a farmer known for his ingenuity and work ethic. He and other members of the family built the farm’s buildings and grain handling facilities, and this inventiveness is in Keith’s blood. “I enjoy building and designing things,” he said. “I am self-taught with some experience as a mechanic and heavy equipment operator, but this malthouse project is by far my biggest yet.”

In 2018, Keith began to ponder the possibility of a malthouse. “I am a scotch drinker at heart, so I initially wondered if we could produce malt to make whisky,” he said. Fascinated by their research into the malting process, the Woynorowskis committed to launch their own malting business and priced out ready-made malting units. These proved too large, expensive and difficult to acquire. Keith’s DIY DNA kicked in, and the rest is micro-malting history. He spent months reading books and online sources about malting biochemistry and process specs.

Scouring Kijiji for stainless steel tanks, Keith purchased a 2,200-litre dairy tank and began the construction process. “A dairy tank made an excellent vessel to start building around, and I got some of the parts from my local auto supply store,” he said. Within a year, he also located a “killer deal” on a 15,000-litre tank that would allow for an eventual expansion. To recycle the heat from the exhaust produced during the kilning process, he built a heat exchanger that forces the high-humidity air through a series of small tubes that warms the incoming cold air.

As a labour saver and safety aid, he then constructed the aforementioned pneumatic tube system to minimize the physical handling requirements of the barley. “I was constantly loading and emptying product, having to handle it multiple times before the malt was ready to go,” said Keith, of the system’s pre-tube days. While making the use of a forklift unnecessary in moving the grain from stage to stage, the system also eliminates dust and the need to wear a respirator. Additionally, it is gentle on the grain. “Malt is very delicate. Every time you auger it, you do a lot of damage. Pneumatics is definitely a little bit easier on the product.”

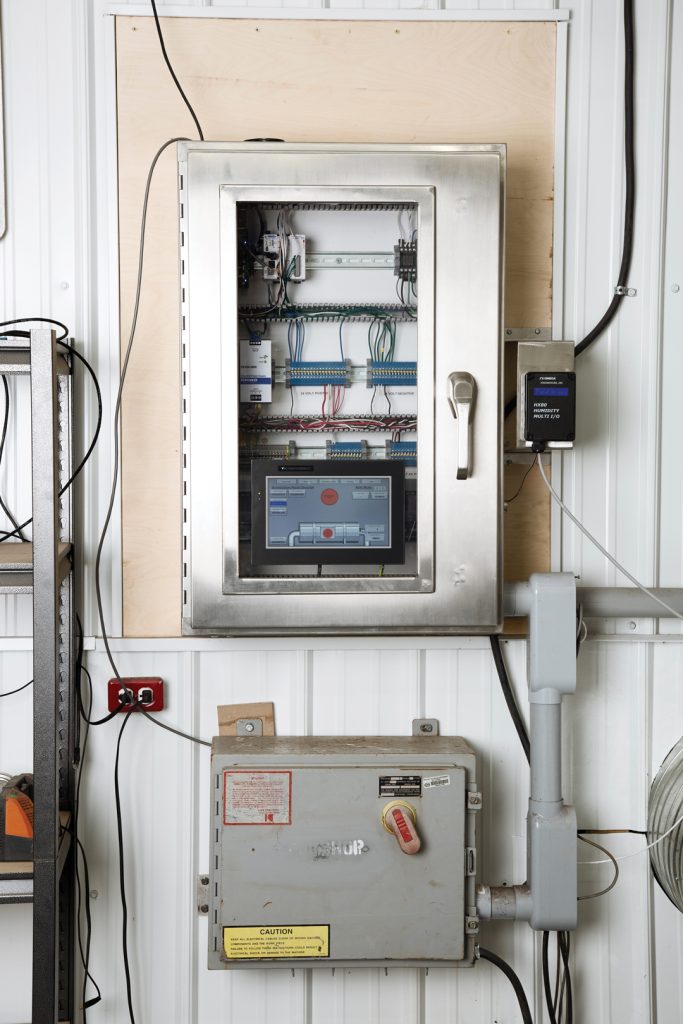

A further indispensable labour-saving component is the malthouse’s programmable logic controller (PLC). The industrial-strength computer system monitors and controls its functions, which allows Keith to carry out his farming duties. The digital system operates the entire malting process including temperature and humidity within its vessels 24 hours a day. To create it, Keith taught himself to write computer code. “I never thought I would have to learn to write ladder logic [PLC software], but you do what you need to when you are running things on your own,” he said.

The couple also attended the two-week intensive malting course offered by the Canadian Malting Barley Technical Centre in Winnipeg, MB. Jennifer took the course first so she could provide feedback as Keith worked through the construction process of their malting unit. Once the system was complete, Keith took the course in part to compare his newly invented malting process with that of Jennifer’s training course. He found they were indeed comparable and appreciated the course’s hands-on malt production aspect. He did admit he would have benefitted from on-the-job experience in a malthouse. “There are always going to be variants on your way up to those [malting] benchmarks. You can’t learn that all in one batch.” True to form, he and Jennifer have studied the finer aspects of malting theory and perfected procedures on their own through trial and error. “We’re still learning,” said Keith.

While the couple worked together on the system’s design process, Jennifer now handles the books, conducts sales and makes deliveries while she also cares for the couple’s three school-aged children. She plans to eventually take on more work within the malthouse itself.

THE SCALE UP

The couple’s ambitious plan to have the system ready for the fall 2018 barley harvest fell through in part because the crop lodged and wasn’t of the quality Keith was after. The system was ready to go and the crop a winner in fall of 2019. The one-tonne capacity system wasn’t as efficient as he initially hoped and its first run produced just half a tonne of malt, but the quality was there. “The dairy drum worked really well, and we ended up with a very uniform product,” he said.

The malthouse does double duty as the farm shop, and Keith built the first iteration of the malting rig on wheels so it could be moved around the space as needed. He continued with the small system for 18 months, but demand rapidly outgrew supply as Hammer took on new clientele. In the summer of 2021, Keith rebuilt the system around that second, larger dairy tank with its four-tonne capacity. Hammer’s 15-tonne annual output jumped to 25, with the goal to produce more than 60 tonnes in 2022.

PRODUCT DEMAND

Most Hammer clients are located within a one-hour drive of the malthouse. In keeping with the preferences of the craft sector, the Woynorowskis promote their malt as local, high-quality and exceptionally free of chaff. Derived from AAC Synergy, it is low in glycosidic nitrile, which also makes it desirable for whisky distillers. “We treat it like we are seed growers and only collect the best of the crop,” said Keith. “This increases the chances of producing a high-end malt tenfold.”

The Woynorowski family grows malting barley entirely without the use of glyphosate. Though not an organic operation, aside from some recent flea beetle control in the farm’s canola acres, they typically don’t apply pesticides, period. The two quarters that supply the farm’s raw grain are worked as sustainably as possible, with limited nitrogen application and minimal equipment passes. Interestingly, these agronomic practices have not proven key sales features. While buyers certainly appreciate them, field traceability has been a somewhat bigger draw, said Keith. However, he has found simply opening a bag for a potential client, its apparent high quality clinches sales. Its performance in the malting and brewing processes have subsequently earned customer loyalty.

The expanding Hammer Malt product line includes base and specialty malts, with pale and Pilsner styles being bestsellers. Hammer also produces wood-fired special roast malts and peat-smoked malts.

Similar to a coffee roaster, Keith built a wood-fired, drum-style roaster. Situated outside the malthouse, it imparts a subtle campfire quality that stops short of smokiness. “It’s like when you cook dinner over a campfire,” said Keith. “It just has that full-bodied flavour. It’s definitely unique.” He believes the malthouse is the only Canadian maltster to produce such products, as most use commercially available gas-fired systems.

Yet another homemade rig, Keith also utilizes a smoker to produce peat and wood-smoked malts. The invention of this unit was particularly challenging, as it was tough to get the peat to burn at a continuous rate. With a great deal of time and effort, he devised an efficient proprietary system. He believes it is the only unit of its kind in Western Canada, and demand has multiplied. While the device has limited capacity, he has devised a means to smoke three tonnes of malt at a time in the large dairy tank.

CUSTOMER SATISFACTION

Sturgeon Brewing of Morinville was the first Hammer Malt client. Owners Josh Watson and Kerry Lamoureux were longtime homebrewers prior to the launch of their business in 2020. They were keen to purchase locally grown malt and connected with the Woynorowskis as the budding maltsters built their business.

“We were able to develop our products and our quality controls together,” said Watson. “Keith malts the barley and we see how it performs. If we hit our targets, we knew we were on the right track. Keith can fabricate a solution to any challenge he is presented with. He was meant for this kind of business.”

“If some element is missing from our malting process on day one, it will cascade to a bigger problem on day 10,” said Keith. “Nobody sees that more than the brewer.” Sturgeon’s help allowed him to adjust the various stages of the malting process to deliver best results.

Sturgeon and Hammer even teamed up to develop The Good Chit malt. High in beta-glucan, chit malt is blended in small amounts with other malts primarily to increase foam stability in beer, which increases head retention.

The Fort Distillery in Fort Saskatchewan creates small-batch spirits. Head distiller Julia Le has worked with various maltsters in the past to create vodka, gin and whisky. Rather than import malt from overseas, she approached Hammer as a local source.

“Keith is an innovator through and through,” said Le. “We were looking for a peated malt to use in our whisky. We wanted an Alberta-based product with our own custom specs—something nice and smelly, like a campfire. We worked with Keith to dial in exactly what we wanted, and he worked to create that effect. Every new batch is better than the last.”

Word has spread about Hammer’s increased production capacity and customized smoking capabilities, and the maltster has taken on a large new distilling client this year. “I hope we will have enough capacity for the next few years,” said Keith. “If not, I’ll build some more.”

Comments