SCIENTIFIC ASSESSMENT

BY ELLEN COTTEE • PHOTOS BY LEIF NORMAN

With its research into end-use functionality—or baking characteristics—monitoring and analytical services, the Canadian Grain Commission’s (CGC) Grain Research Laboratory (GRL) plays a key part in supporting Canada’s grain quality assurance system. Esther Salvano assumed directorship of the lab in July of 2019, bringing with her an affinity for the strong science-based programs and policies the agency maintains.

GrainsWest: You’re from Quebec City and completed your schooling in Quebec before moving to Winnipeg. What drew you to the agriculture industry?

Esther Salvano: I did my bachelor of arts in microbiology at l’Université Laval, and my first summer job was looking at soil health and water quality in cropping systems. It was a really rewarding position. When I decided to go back to school for my PhD in water sciences through the Institut national de la recherche scientifique at l’Université du Quebec I knew I wanted to put it to use in the agriculture industry.

GW: How did your previous positions with Agriculture and Agri-Food Canada’s science and technology branch and Manitoba Agriculture prepare you for your role with the GRL?

ES: The main thing they taught me was the role of agriculture across the Prairies, and how sustainability is important for the industry. I also worked with great people who taught me about establishing trust with collaborators across the value chain.

In my experience as the science and technology director for Manitoba, I learned more about research, grading technology and other disciplines such as breeding, pathology, genomics and proteomics. The learning there was more focused on the type of science that the federal government is doing. I also learned how to best use science-based information in the development of programs and policy. This is an important part of my job and the CGC vision of being a world-class, science-based quality-assurance provider.

GW: What drew you to the position of GRL director general?

ES: It was the opportunity to work with producers and industry while advancing scientific research and supporting the grain quality assurance program, as well as research methods for grain quality and safety. It’s a great place to work. I’ve been impressed by the skill and dedication of our staff, and I want to support them as they help the CGC achieve its goals and meet its mandate.

GW: What does the next year look like for the GRL?

ES: The research conducted by the GRL falls under two categories: crop research and technology research. Our research related to crops assesses Canadian grain harvest quality and studies how grading factors affect end-use properties. Crop research also develops new uses for Canadian grain and evaluates new varieties as part of the variety registration process. Research related to technology evaluates and develops methods used to assess the quality and safety of Canadian grain. We’re always making sure our grading system is supported by science, that Canadian grain performs consistently and is dependable, reliable and safe.

GW: One of the most important programs the CGC operates is cargo quality monitoring. How has the program evolved?

ES: The program has existed since the 1960s as part of grain quality assurance. When grain is loaded onto vessels, we take samples and conduct analysis to generate data for Statements of Assurance. These give exporters and importers science-based assurance that Canadian grain meets safety requirements. We also monitor export wheat shipments for wheats of other classes and ineligible varieties as these could undermine quality and create problems for customers. Countries have certain guidelines on grain they wish to purchase regarding quality, tolerance for issues and GMO. In 2017, GMO wheat was found in Alberta [this was made public in spring of 2018]. Our cargo testing confirmed it was an isolated incident and that GMO wheat is not present in the Canadian grain handling system.

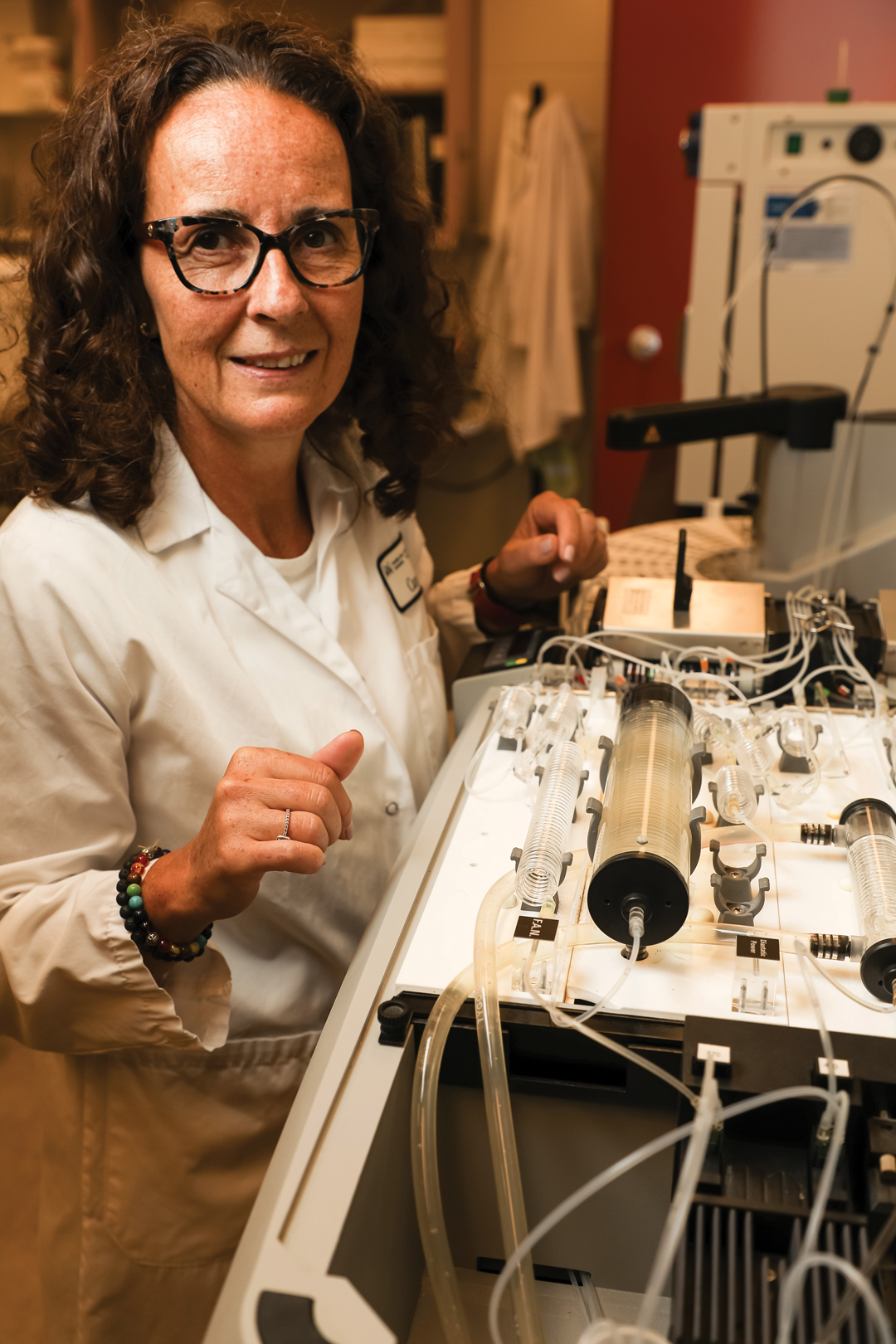

Esther Salvano oversees CGC research into new uses for Canadian grain as well as development of grain assessment technology.

GW: CGC runs the Harvest Sample Program, carrying out quality testing and unofficial grading on samples submitted by farmers. How do you ensure the program keeps up with changes in the industry?

ES: The Harvest Sample Program has been running since 1927. Of course, there have been plenty of changes over the years. We provide participating producers with email results. This was a change that helps producers get their information faster and easier. On the development side, we now provide results for DON [vomitoxin] levels in wheat and corn samples and falling number in wheat.

Each year, we receive nearly 11,000 grain and oilseed samples from 2,700 producers. In 2018, we received over 12,000 samples from nearly 3,000 producers.

GW: Why should farmers participate in the program?

ES: The grades farmers receive allow them to properly market their grain. They also receive other quality results like protein content and detailed information on degrading factors fundamental to knowing the grain’s value. When delivering grain to elevators, farmers will be more informed as to what they have in their bins. Farmers’ samples are crucial to help the marketing of Canadian grain, evaluating our grain grades and research that benefits producers, including finding new uses for grain to help create new markets. We use their samples to make crop quality data available to marketers to promote the sale of Canadian grain.

GW: Technology is changing all the time, especially in agriculture. How does the lab keep up?

ES: Research and investment in new technology is a big part of our work. A good example is near-infrared spectrum spectroscopy (NIRS). It’s an important analytical tool for the job that uses statistics to develop mathematical models to predict quality parameters.

Every year, our lab analyzes samples from the Harvest Sample Program and we add them to the calibration model to assess if the calibrations are working for that year. Over the years, the GRL has assembled a database of samples that can be used by producers, marketers and other stakeholders to develop their own calibrations. This is advantageous as some of the reference analyses are difficult to do and sometimes people do not have the expertise nor the instruments to do them. Getting a calibration set with data that you trust is important.

We’re also doing a lot of work on a fast, reliable network to track grain quality.

GW: How does the lab employ biotechnology and what kind of projects can it be used for?

ES: We use it in the GRL for the detection of GMOs in grain samples. Again, this testing is done because of labelling and regulatory requirements established by many countries for unapproved GMO events. The EU has a zero-tolerance policy for unapproved GMO, for example. The CGC has been internationally accredited for the testing of grain samples for the presence of GMO since 2013, and that provides international recognition. Of course, we’re always looking at new equipment, methods and challenges for the industry.

GW: What are you most excited about accomplishing in your new role?

ES: In the next few months, I’m looking forward to spending time with the scientists and programmers and learning about the research and science that is happening in the lab, which will allow me to understand how best to support them to do what we do best.

Comments