REAL-TIME REVELATIONS

BY MELANIE EPP • PHOTO COURTESY OF AGRITECHNICA

In Canada’s short growing season, having the ability to make quick decisions based on accurate information is a plus. In recent years, revolutionary new sensor technology has come to market. Its aim is to aid grain farmers in making decisions that improve crop production and quality. These new technologies allow farmers to assess soil quality and fertility in real time and evaluate the results of their fertility plans. This writer attended Agritechnica 2019 in Hannover, Germany, and discovered three such systems that may have applications in Western Canada.

WHEEL OF FORTUNE

SoilReader is a precision soil analysis tool that provides real-time, multi-constituent, variable-depth and on-the-go information on nine soil components. Essentially, it is a coulter fitted with a spectrometer that collects and analyzes data as it cuts through the soil.

Cal Harrison, SoilReader vice-president of marketing, said the company chose to launch its product at Agritechnica because he believes the technology will be relevant to farmers worldwide.

SoilReader now measures nine constituents: nitrogen, phosphorus, potassium, soil organic matter, moisture, clay, sand, electrical conductivity and pH. The company believes it can raise the number to 22 constituents before running out of measurables. The sensor collects approximately 6,900 data points per acre, and SoilReader feeds constituent data right into the cab or in real-time to a variable rate applicator. Cloud connectivity is not necessary for the application to function.

“Imagine a giant pizza cutter attached to a farm implement that’s being dragged through the soil,” said Harrison. “As it’s going through the soil there’s a little light going around and around on the side. As the light goes into the ground it reflects against the soil that it’s cutting through. The light comes back through the device, and that’s how we determine, using a spectrometer built into the hub, what’s in the soil.

“We’re excited to bring SoilReader to the market because we think it’s going to revolutionize the way we look at soil and the way we manage soil. We believe if we want to better manage our soil, we have to measure it better.”

Saskatchewan grain farmer Terry Aberhart is excited about SoilReader’s potential. Aberhart farms about 15,000 acres on the Saskatchewan-Manitoba border. He grows canola, wheat, malt barley, pulses, hemp and other specialty crops. He also owns and operates Sure Growth Solutions, an agronomy consulting company.

In 2018, When Harrison first approached Aberhart at the Farm Forum Event in Calgary, he was excited yet skeptical to try out the technology. “A lot of new technology isn’t always what they say it is,” said Aberhart, who agreed to try it out. “What I really like about the concept of the SoilReader—if we can get to where we want to go—is basically having the ability in the future to do variable rate applications in real time.”

One of the main limiting factors of precision agriculture is the sheer number of fields that need to be sampled in a short time. SoilReader could solve this problem. “I think there’s still a bit of work to do, but the potential for SoilReader is game changing,” he said.

Aberhart sees SoilReader as a great add-on for existing machinery such as tillage or harrowing equipment. It could also be mounted straight on the drill or fertilizing unit, he said. At press time, Aberhart was scheduled to begin working with the first beta units, which were to be marketed in Western Canada in August 2020.

A PLAN TO SCAN

Last year, Dutch company AgroCares signed a partnership with Canadian company Concentric Ag Corporation, a major developer of biological and plant nutrient inputs.

This allowed Concentric to distribute the NutriScan system.

NutriScan is a hand-held device that uses AgroCares sensor technology. It collects real-time soil nutrient data and provides crop advisors, agronomists and researchers with complete soil nutrient analysis plus recommendations. The results are sent to the user’s smartphone within just 10 minutes.

“Soil analytics is an integral part of our long-term business plan,” said Jarrett Chambers, Concentric executive vice-president and chief commercial officer. “We believe NutriScan’s real-time diagnostic tool will further help Concentric’s growers apply the correct nutrients to maximize the genetic potential of their crops.”

The scanner offers users several benefits. It allows them to instantly check soil quality when deliberating on the purchase of new land. It also allows them to quickly determine which fields are best suited to which crops. It enables farmers and agronomists to monitor fertility developments throughout the growing season and empowers them to make fertility decisions that could sustainably improve soil health, while increasing yields.

NutriScan measures nitrogen, phosphorus, potassium, pH, cation-exchange capacity, soil organic matter, macronutrients such as zinc, boron and copper, and intermediary nutrients such as calcium, magnesium and sulfur.

NutriScan’s most notable feature is its response time. “For no extra charge, it allows you to break out your production sites into different zones,” said Chambers. Additional benefits include ease of use.

Last year, Concentric invested nearly $250,000 to set up a third-party lab to help with calibration of the analytical equipment in Canada. It is Concentric’s aim to distribute the product only, while a partner company will run the lab.

NutriScan will be commercially available in the fall of 2020. The total cost of the package is $5,000 for the unit, plus an annual subscription fee of $5,000 for the complete package. Lighter subscription packages may also be available. Ultimately, the unit is designed for users who do more than 100 soil samples per year, said Chambers.

FIND THE SWEET SPOT

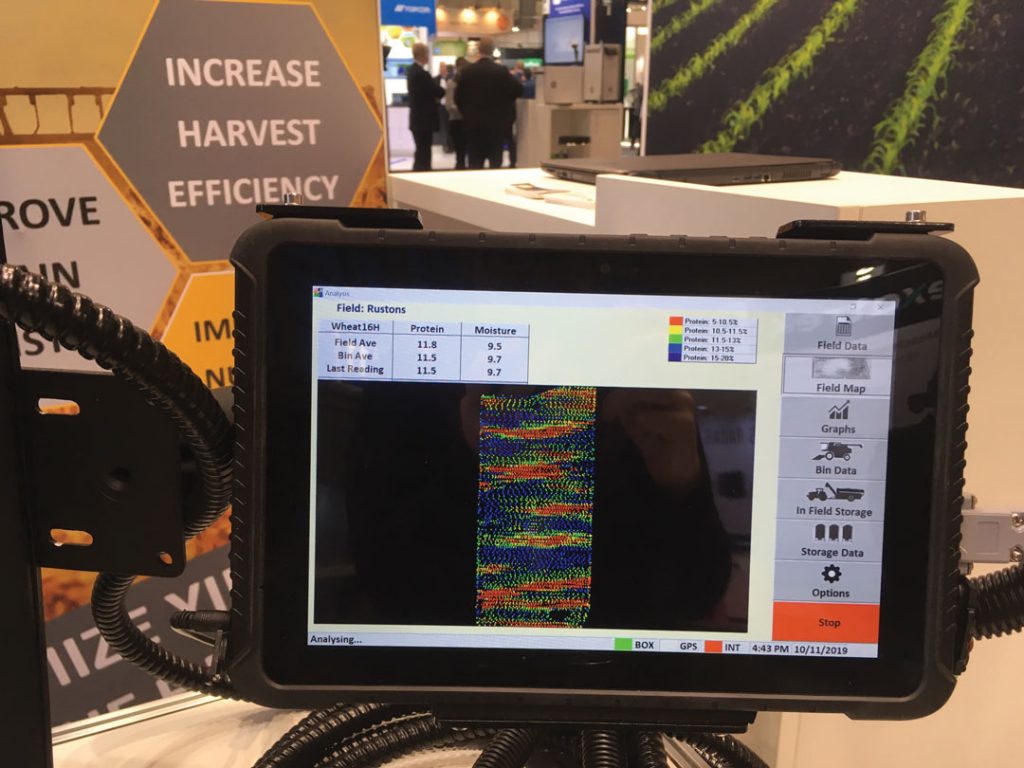

Taking yield mapping to the next level, Australian tech company Next Instruments has developed CropScan 3300H, an on-combine grain analyzer. The CropScan kit includes a NIR analyzer, a remote sampling head and a touchscreen display. Every six to 12 seconds, it measures protein, oil, starch, fibre and moisture as grain is harvested. The device provides farmers with real-time field maps and allows them to segregate and store grain by quality. CropScan also includes grain logistics software with blending estimation to help optimize crop payments.

Certain farmers will use it to segregate grain after harvest, while others will blend it to take their grain to a higher grade, said Next Instruments marketing manager Victoria Clancy. Others use the data to make protein maps they overlay with yield maps from the combine. They use these maps to further enhance variable rate strategies. “For wheat and barley, optimum protein is between 11 and 12 per cent. If you don’t reach that 11 to 12 per cent, you’ve actually limited the yield that crop is producing,” said Clancey. “In order to maximize the yield that crop is producing, you actually have to make sure that you’re reaching a certain protein level.”

Farmers aren’t just using CropScan to measure quality. “We’ve got farmers who are using the protein information for their variable rate applications and have levelled out the yield variability across their farm by about 40 per cent,” she said. “Especially if it’s a drought year or it’s weather-affected, having farmers that are above the average for the yield and the quality in their region based on using the protein information. You know, that’s all extra money that they’re making.”

Alberta-based independent crop advisor Steve Larocque bought a CropScan 3300H unit in 2016. Larocque manages more than 30,000 acres of cropland and planned to use the device as a research tool to better understand nitrogen mineralization rates. He also wanted to understand protein and how it varies spatially across a field.

While it worked well in the first year, he said he had water issues in 2017 and 2018. “They’re built in Australia,” he said. “I don’t think they were used to Canadian winters and snow melts.” Next Instruments sent Larocque another model, a sealed unit with one motor instead of two, so he was able to collect data again in 2019.

While Next Instruments promotes the scanner as a device for segregating grain, Larocque bags most of his, which makes segregation challenging. “If you’re set up to segregate grain, that’s great,” he said. “I think it’s totally doable.”

He still thinks the math on grain segregation is tricky, though. “What is the value … if you can elevate the whole average to 13.5 per cent protein versus segregating off a certain percentage of, let’s say, 15.5 per cent protein?” he said. “Are you better off? That’s the math I haven’t been able to do.”

Larocque won’t know which fields, if any, are consistently high protein grain producers until after this year’s harvest, as his four-year rotation cycle will begin again this year.

What he really wants to do, though, is to hone in on his nitrogen fertilization rates in order to better understand where he’s getting greater mineralization. He’ll then compare that data to conditions the crop was grown under in order to see which biological, chemical or structural parameters generate higher protein. He also wants to know if there are any correlations between pH, electric conductivity, nutrients or protein.

“It’s a tool to help fine tune your zones, your yield potential inside of each zone, and your proteins, which is ultimately a reflection of your mineralization rates,” said Larocque.

“At the end of the day, the whole trick is to get high yield and high protein, and the two rarely meet. So, where is the sweet spot, right? CropScan will lead you to it because you’re logging yield and you’re logging protein at the same time.”

Comments