BEER AND BLOCKCHAIN

BY SAM GREEN • PHOTOS COURTESY OF HOT SHOE STUDIO

Nearly everyone has heard of it, but almost nobody understands it. It has the potential to transform the way we manage supply chains, track and verify sustainability certifications, market and sell commodities and interact with consumers.

Blockchain is more than a mere buzzword. Where agriculture meets digital currency, it has the potential to revolutionize the way we get our food from farm to fork. Before we can fully appreciate its applications in the agri-food sector, it is important to understand exactly what it is.

While the technicalities of blockchain can be quite complex, its basic principles are fairly simple. Essentially, it is a new record-keeping mechanism that replaces double-ended bookkeeping and centralized ledgers. It allows information to be stored on a distributed network that, by virtue of its design, renders the information unchangeable, permanent and instantly accessible to all parties involved.

When applied to the agri-food sector, this innovation has profound implications. Primary among these is increased transparency and traceability in the supply chain. In fact, a blockchain driven supply chain allows all participants—farmers, processors and consumers—to have complete and accurate information about products, from how and where they were grown to when and how they were processed. This is perhaps best understood by way of example, and we don’t have to look far afield for a real-world agri-food blockchain in action.

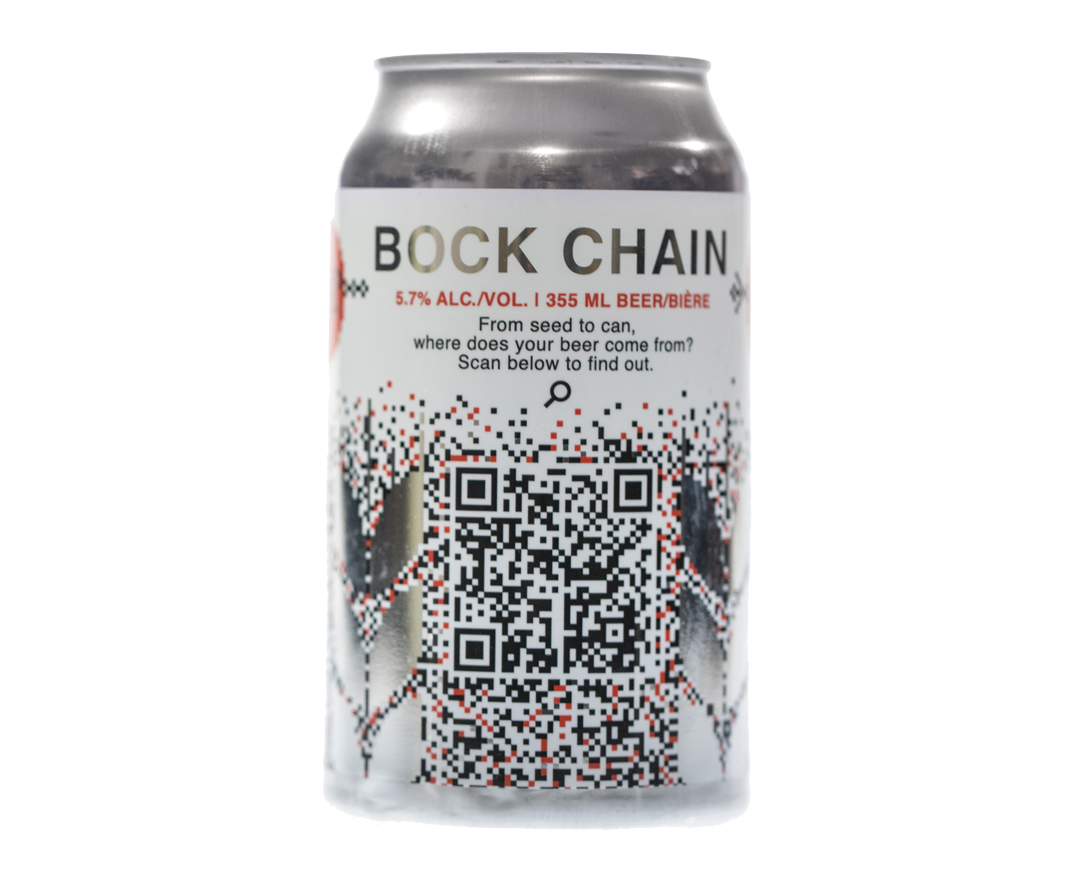

Bock Chain beer, so named for the digital currency trial it represents and the German-style lager it is, was officially launched in Jasper on Feb. 1, 2019, as a collaboration between Hamill Farms, Canada Malting, Red Shed Malting, TE-FOOD and Last Best Brewing and Distilling. Its distribution incorporates blockchain technology to store and share the story of the beer’s transformation from field-grown grains to freshly brewed beverage.

“It’s a beer that takes traceability to a pretty intense level, using blockchain technology to follow the barley from the farm, through the malthouse, through the roasting, to the brewing,” said Matt Hamill, co-owner of Red Shed Malting.

For farmers such as the Hamills, this increased traceability through a blockchain means they can back up the claims they’ve made on production methods and locality by providing partners and end users with complete and verifiable information about their product.

“The reason that we at Red Shed were excited about it is that our sales points on our malt are that it’s local, sustainable and traceable, and blockchain is pretty cutting edge on traceability,” said Hamill. “It lets us walk the talk.”

Each can of Bock Chain includes a QR code on the label that, when scanned, takes the consumer to a microsite containing details about the beer and its production, including photos, maps, time-lapse videos, data and timestamps for such things as planting and harvest dates. Consumers can get more information about each stage of the production process including company biographies, lab test results and malting information from the website.

It is indeed becoming increasingly important for the agri-food sector to walk the talk when it comes to claims of sustainability and production methods. Consumers have become more conscientious about the food they eat and look for products they can consume with confidence. They want to know the claims being made on labels are accurate without having to dig through scientific data.

“You see more and more of a disconnect between urban and rural. I think people in the cities want to know more about where their food is coming from and want some of that story. At the same time, they don’t want to be bombarded with a bunch of science or a bunch of technical stuff,” said Hamill.

“Bock Chain is a way to say there’s a cool story with the ingredients that are going into this beer and we’re pretty proud of the way it was farmed, the way it was malted. We’re excited about it and we’re completely transparent, so you can watch that field grow from the time it was seeded to the time it was harvested.”

Natasha Peiskar, head brewer at Last Best Brewing & Distilling, agrees. “I think consumers are really starting to become interested in where their food and beverages come from. Using blockchain technology with Bock Chain, we were able to show the field-to-can perspective. Consumers are becoming much more savvy about what they are buying and there was some excitement about knowing that, for example, the barley used in this beer was grown right here and the malt produced in Alberta.”

The clear winner in projects such as this is the consumer. They suddenly have access to an amazing amount of information, and perhaps more importantly, the story behind the product. But blockchain also offers advantages to other supply chain participants.

“For Last Best, there is an integrity level that plays into it, too. We already have really good relationships with our suppliers, but knowing exactly what came off which fields and even third-party lab results for quality assurance brings a new level of integrity to the product we’re buying.”

“For us, this was a proof of concept,” said Kyran Flett, Canada Malting sales manager. “We’ve gone from hand ledgers, to Excel spreadsheets, and now blockchain. We do this traceability without this technology today, and this was a way to see how blockchain technology might feed into our business and improve efficiencies. I think it will slowly move towards where one day, we are using some form of this technology for all of our barley.”

There is plenty to be excited about as blockchain technology is trialed and adopted into agri-food supply chains, but there are real barriers to overcome before widespread implementation is possible.

“Cost is one, too, but I think updating everything for sensor integration is the biggest limiting factor,” said Flett. “You need a sensor on the combine, the old barley elevators, the malthouse … but when you look at this over a 20-year period, that probably looks fine.”

Using sensors, many new farm machines, especially equipment in the precision agriculture category, now collects the necessary information. It is just a matter of collating it, getting it onto a blockchain and communicating it along the supply chain to consumers.

Blockchain creates potential for farmers to market highly localized and specialized products such as a batch of wheat from a specific field grown under certain conditions and harvested at a certain time. To achieve this, though, farmers will need the ability to segregate batches of their product for specific customers. “If you wanted to have a different bin for every customer or every field, you would run out of space pretty quickly,” said Flett, who noted this may be a limiting factor for blockchain adoption. Storage capacity will need to be greatly expanded or new ideas for separation brought forward.

Large-scale implementation of blockchain technology in the agri-food sector supply chain will take time as these barriers and limitations are worked through. Specialty crops such as malt barley will be the first to take advantage of this opportunity, but others will follow as the kinks are worked out in bulk processing and handling systems. QR codes could become a permanent fixture in the grocery stores of tomorrow.

For now, projects such as Bock Chain illustrate the immediate benefits this technology can have for farmers, processors and consumers alike. While the rest of the ag industry catches up, enjoying this first sudsy taste of what blockchain can accomplish is a delicious start.

Cheers.

Comments