DATA UPGRADE

BY TREVOR BACQUE

Ag continues to digitize at a rapid pace. The ag sector is increasingly more about automation and AI and less about buttons and belts. Throughout the industry, bright minds and innovative companies take risks and push toward data-driven solutions. GrainsWest sat down with five organizations that aim to make life easier and more profitable for farmers while attempting to derisk and demystify emerging tech.

Optimal recommendations

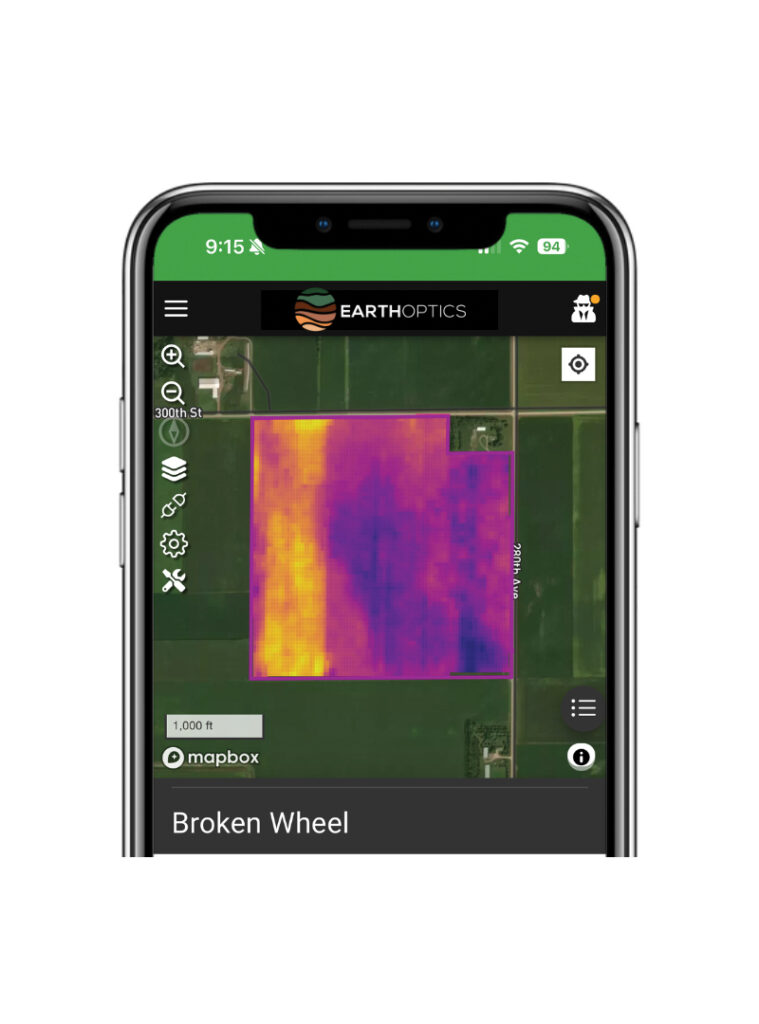

EarthOptics

What a difference one year makes. For EarthOptics, the last 365 days have been a whirlwind. First, the company acquired Pattern Ag, an American business that aimed to revolutionize farming with the use of biological indicators to predict agronomic outcomes. This suited EarthOptics, which was founded in 2019 to provide quality soil data to farmers and ranchers through a trio of mapping—carbon, compaction and nutrient. The company in turn morphs this information into highly accurate data maps that picture the biological, chemical and physical makeup of the soil.

The company focuses on taking fewer soil samples to make it more cost effective and produce high resolution maps. Combine this with DNA testing and soil biology, the EarthOptics team feels they have a winning formula to offer more information to farmers about their dirt than ever.

The company has recently shifted gears toward its new crop management tool. It loads all the biofertility, fertility, pathogen and pest risks and opportunities onto the EarthOptics’ dashboard. It provides a field map, recommendations and automated fertility prescriptions. The recommendations include seeding and input rates as well as optimal spraying times. It also details the optimal timing to apply biologics and biostimulants.

“It takes a lot of the guesswork out of putting together a crop plan and makes it an entirely data-driven exercise that can even be automated. By pressing one button instead of a week-long planning exercise between farmer and agronomist, you make all the key agronomy decisions for that year,” said EarthOptics CEO Lars Dyrud.

The ability to simplify operations with precision ag is what most farmers want these days, he added. “It’s taking something that is an experience and gut-level decision like, ‘What seed am I selecting?’ and having concrete data to drive every decision we’re making on this particular field. And we know because of the data; we’re optimizing our decisions around the best outcomes possible.”

While the product is primarily situated in the U.S., farmers in Canada, Brazil and other jurisdictions also have access to EarthOptics’ tech.

The program is run on a per-acre cost at a rate of $5.72/ac (US$4/ac).

Make the grade

Ground Truth Ag

When Kyle Folk launched his business in 2022, he had a simple yet audacious goal: To benefit farmers, make grain grading more accurate and consistent. Traditional grading is not perfect and never has been. However, he was convinced that mechanization could make the process better than ever.

He first sampled grain as an 11-year-old driving the family’s grain truck at their Holdfast, SK, farm. Since then, he has come to realize the value of sending samples off to buyers, but also that the results can be imprecise. The grading risks his father shouldered always stuck with Folk and would eventually lead to the creation of Ground Truth Ag.

From the start, the feedback was clear. An attempt to build automated grading machines with improved accuracy had been tried and failed, so do not waste your time. “Today, it’s the opposite,” said Folk, who sought to prove the skeptics wrong. “Everybody has seen what we’ve done, and they all see that it works. It just keeps getting better. It’s no longer a mountain that can’t be climbed.”

The company had initially focused efforts with on-combine grain grading. While it still works to build that market to a commercial release, it has largely shifted focus with the introduction and subsequent popularity of its benchtop unit used at country terminals. The unit is in the early commercial phase of development.

An 80 per cent accuracy rate is the generally accepted guideline for personnel who carry out grading at CGC-licensed grain elevators. Though not a pretty number, it’s the reality. “Grain buyers don’t want their grain to be subjectively graded, they want it objective, but it’s hard when humans are responsible for grading the grain,” said Folk. “Inevitably, you end up with this process that gets questioned.”

Today, the Ground Truth benchtop unit can grade grain for protein, moisture and defects through visual and non-visual grading factors. This is achieved through NIR spectroscopy, machine vision and machine learning technology that can analyze the inner and outer kernel.

As an example, Ground Truth’s unit initially correctly graded CWRS at a rate of 85 per cent, which has only gone up as the machine has been fine-tuned. The product is sensitive enough to determine, for instance, an accurate mildew damage rating of light, medium, heavy or severe. “We are just getting started,” said Folk, of the machine’s expanding capability. Feedback from grain buyers has been overwhelmingly positive, and they are pleased to see a machine that produces results with greater accuracy, he added.

The benchtop unit can now grade spring wheat, red lentils and soybeans. This year will see the addition of corn, durum and oats to its grade modelling algorithms.

In a world increasingly powered by AI and machine learning, Folk believes greater accuracy and consistency in grain grading can become a reality for farmers. “This tech was created to provide consistency to the process and remove fragility in the supply chain,” he said. “Until this is mainstream, I feel like the job is not done. We need to keep pushing forward and get the product out there, get it used, adopted and be standard issue. If we get buyers to start using this, then everyone in the industry will use it.”

Know it all now

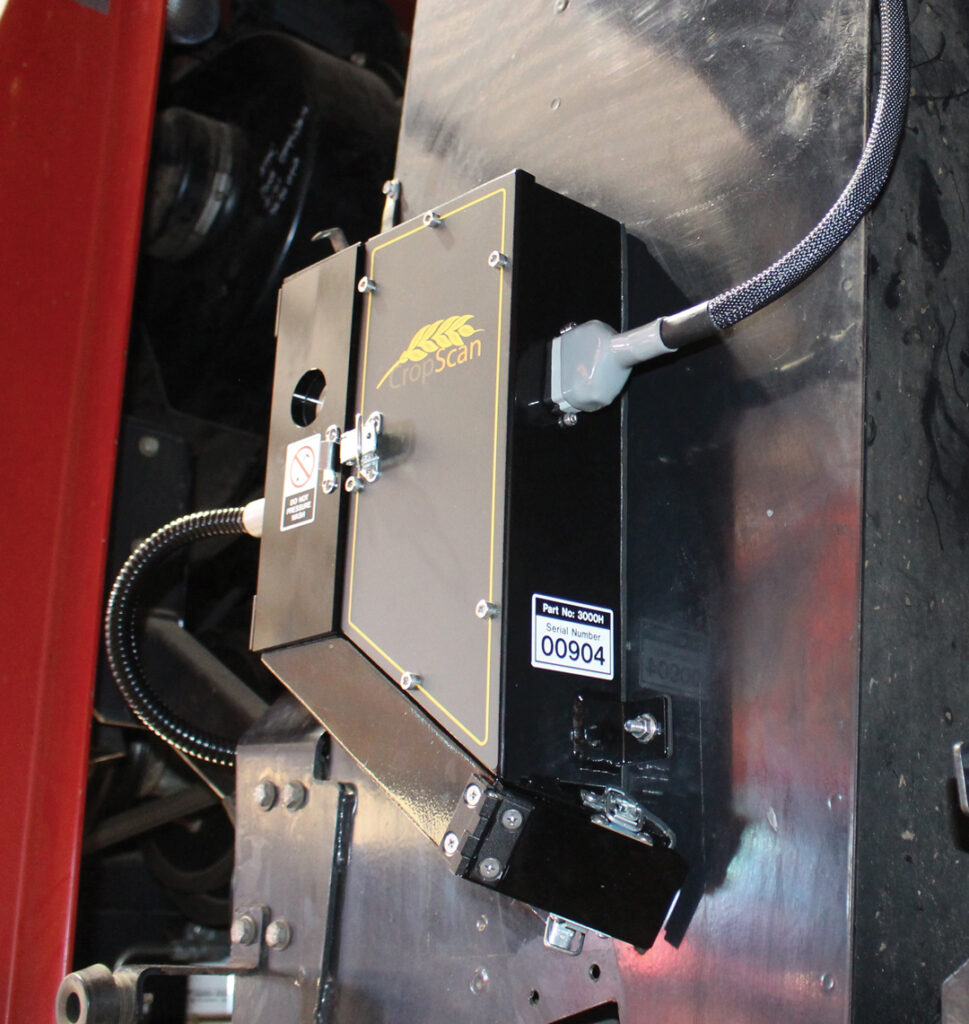

CropScanAg

Developed in Australia, but used globally, CropScanAg has created a new on-combine grain analyzer to give farmers up-to-the-second results. Its newest model, the 4000VT and corresponding N-Gauge app, challenges the notion farmers can’t know everything about their grain the instant it’s harvested.

The device links directly to a combine’s ISOBUS system via the wiring harness and has been specifically designed for CNH machines. The company is in talks with multiple combine manufacturers to see the 4000VT integrated with their ISOBUS systems as a standard feature. Additional combine brands can be outfitted with the company’s 3600H model, which performs the same analysis, but with an extra monitor. “The tech is virtually identical to what the elevators use in their Foss machines,” said Dean Scrivens, the company’s Canadian technical specialist in Camrose.

Powered by NIR, the tool uses light between 720 and 1,100 nanometres to analyze the protein and moisture levels of freshly combined grain. Every three seconds the 4000VT captures data that includes a GPS location of each sample’s field origin. At the same time, the system maps field quality and conditions that can be reviewed as soon as the field is harvested.

With this real-time data, a farmer can make timely decisions. If they’re combining canola and see moisture levels climb, they can choose to stop, continue or put it in a bag or bin. “That’s the immediate use of the data,” said Scrivens. He noted that for CWRS, its accuracy is within 0.2 to 0.3 per cent on moisture and protein, respectively. For barley, it is 0.4 for both measurements, and 0.5 on canola for the same criteria.

The tool shifts the focus solely away from yield, which, although important, only represents part of the picture, said Scrivens. “The problem is, a yield map will simply show low or high yield,” he said. “A farmer would be tempted to put more nitrogen on those [low yield] areas to increase yield.”

The system lets a farmer know where more nitrogen is required. From its field map, the system creates a VR fertilizer prescription for the following year’s crop. Scrivens said a 5,000-acre farm “notices a significant return on investment in the first year.”

The machine is shipped with calibration protocols to automatically analyze almost every crop grown in North America, including barley, canola, chickpea, corn, lentils, oats, sorghum, soybeans, wheat and rice. The benchtop unit, the 3000X, does all these same crops.

Conquer the carbon market

CANZA

The Canadian Alliance for Net-Zero Agri-food (CANZA) continues to push for net-zero agriculture with new initiatives. Last time GrainsWest heard from the organization, it was at work to help lower the cost of soil analysis. As CANZA continues this project it has taken on additional programs.

Managing director Nick Betts was buoyant as he recently discussed CANZA’s latest new project. Over the next four years, it will leverage a $4 million AAFC Clean Tech grant to develop a new soil carbon assessment tool for farmers.

A second initiative underway is the Carbon Impact Project, which seeks to identify and demonstrate collaborative solutions to reduce livestock emissions and provide value to farmers and the supply chain. This starts with assessing the opportunities and challenges of livestock emissions reductions. It is hoped the project will ultimately support market-driven solutions to accelerate those reductions and diversify stakeholders within CANZA’s network. A summary report will be available on CANZA’s website later in the year.

Lastly, CANZA is building an online Canadian platform. Dubbed an Environmental Outcomes Marketplace (EOM), it will help farmers de-risk adoption and advance positive management practices to create tangible environmental benefits. CANZA envisions farmers will access financing or guarantees from investors, agronomic support and potentially even more favourable lending or insurance terms. This third prong is slated to be accessible to Canadian farmers by 2030.

SUSTAINABILITY TRIO

A proper soil spectroscopy assessment is now cost prohibitive for farmers who wish to profit from the carbon market, explained Betts. Lab analysis and sampling are expensive. “We know farmers sequester carbon in their soils, but we don’t have a validated way of measuring it that they can take credit for in an inset or an offset market.” To realize a profit and justify a farmer’s effort, sampling and reporting cost must come down, he added. “We hope to cut it significantly more.”

Ideally, a farmer would do this test with a handheld device or, even better, their phone. To achieve this, CANZA is working with multiple universities on 20,000 acres of western Canadian farmland in co-operation with several farmers.

The second plan is the Carbon Impact Project to identify opportunities for farmers to participate in various supply chains to complete existing carbon projects, such as methane reduction initiatives.

The final component is to create a co-ordinated EOM. This platform will help farmers adopt, and profit from, climate-smart farming practices by offering opportunities to stack incentives for environmental benefits such as improved soil health, reduced GHG emissions, biodiversity supports and improved water quality. “If farmers have to go through all these bureaucratic systems and requirements, it’s hardly worth their time,” said Betts.

The platform will also enable value chains to invest in environmental outcomes as they reduce emissions. Farmers will punch in their location, crop type and in-season practices, to receive a dollar-per-acre offer for that work. “Because we’re streamlining that process, taking away a lot of red tape and providing a platform where these efficiencies can be felt, it’s going to be more attractive to growers,” he said.

With a resilient food system as its primary objective, Betts and his team will build this ambitious project from the ground up. “We are working to make sure these solutions work for farmers and bring them value. This, in turn, will enhance the competitiveness of Canada’s entire agri-food system by securing long-term productivity, food security and economic stability for all Canadians.”

The Marketplace is scheduled to launch ahead of the 2026 growing season. For more information, visit canza.ca.

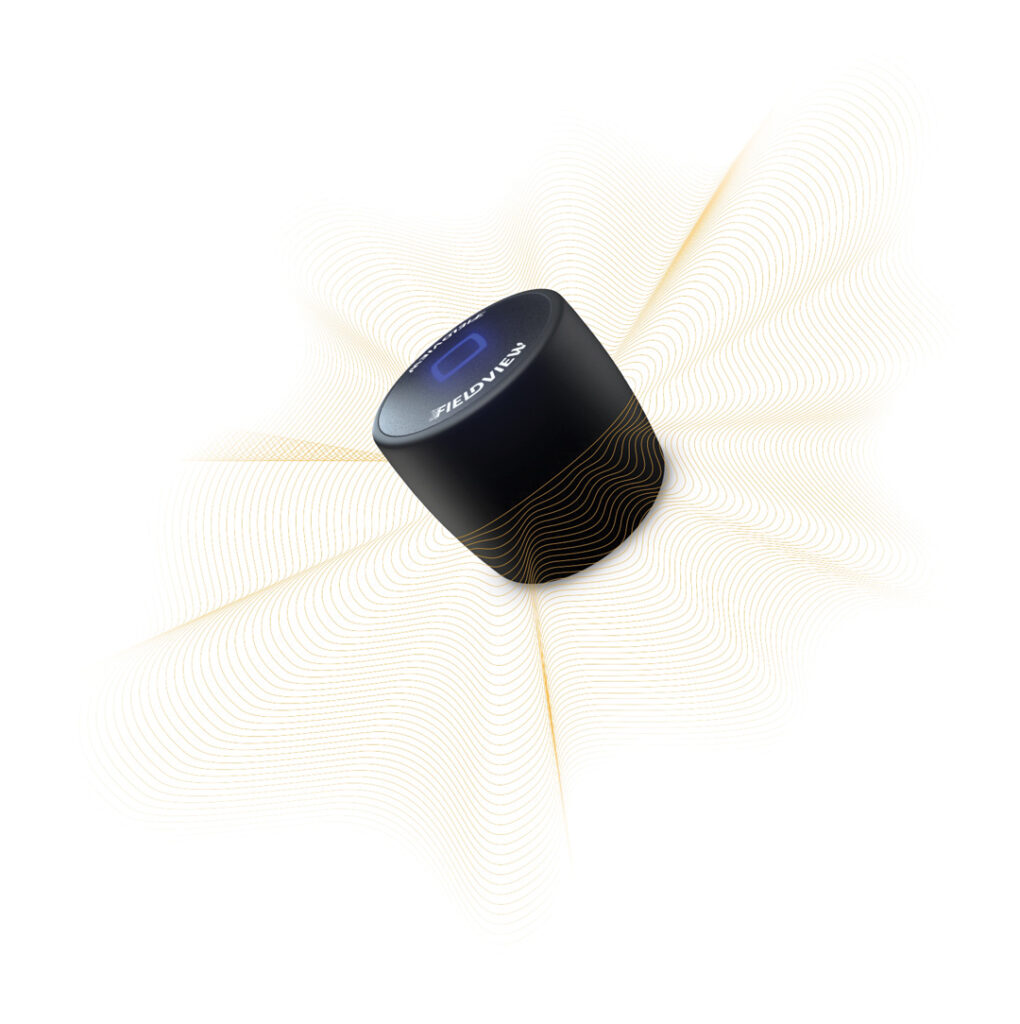

Revised data device

FieldView Drive 2.0

The tractor cab experience continues to undergo rapid change. Designed to boost connectivity and streamline operations to a higher degree, Bayer has launched FieldView Drive 2.0, nearly a decade after its predecessor hit the market. The updated digital tool has greater processing power and connectivity through enhanced Bluetooth, according to Andria Karstens, digital success partner with Bayer. “Having more upgraded technology is always going to be a huge bonus even with simple things like the Bluetooth,” she said.

The device also comes with 32 GB of storage to hold more prescription map data and a more efficient computer-to-cab communication system. In essence, it acts as a lightning-fast wireless transmitter. “We can use it as a transfer device versus needing to have a USB and go back to the office. If something needs updating, we can do that more on the fly, or someone at home can update it and send it to you. It gives us a lot more capabilities,” said Karstens.

Notably, Field View Drive 2.0 does not need a cellular connection for the device to collect data. Once connected to WiFi, data automatically uploads to users’ cloud accounts for secure storage. “It’s the way you’re going to be able to most seamlessly collect and get that field information into FieldView,” said Karstens. “Once it’s in FieldView, there’s a whole suite of analysis tools that lets you identify if what you decided to do makes the most sense for your farm. You can tweak year over year to continue to improve economics and sustainability and make decisions.”

For more information, visit climatefieldview.ca.

The joy of the stick

Pac-Man fans, rejoice! Fendt AGCO has introduced a retrofit for its 500 to 1000 series tractors with Profi Plus with its ErgoSteer joystick. The blast from the past was ergonomically engineered to ease neck and shoulder strain and create less wear and tear on an operator’s forearm and wrist. Its design recently won an award from the American Society of Agricultural and Biological Engineers.

The joystick takes only about 90 minutes to install and requires no software. While it doesn’t replace the wheel, it does serve to provide an extra in-cab function. The joystick has an autosteer button linked to the operator’s GPS. The speed sensitivity can be custom set from left to right, which can provide improved manoeuvrability for faster turns and lower diesel consumption. Without a change of hand position, a slight hand shift is all that’s required for forward-reverse motion. The joystick may also help newer, younger operators get comfortable with the cab.

Coming Soon

The Bluebook app

Since Alberta Grains took on the production of the Blue Book in partnership with Alberta Canola and Alberta Pulse Growers, farmers have told us they would like to see the guide available in the form of a mobile app. Now under construction, we will launch the Blue Book app in January 2026. This convenient, new tool will assist farmers and agronomists as they make decisions about the use of crop protection products. This user-friendly app will be equipped with advanced search capability and offline functionality. Up to 10 products can be downloaded for offline use where connectivity is limited.

Comments