Spring

2018

Grains

West

26

Andrew Lawson, Alberta and B.C.

ESNmarketing rep for Nutrien, said

demonstrating the value of the EEF

products to farmers is important. “ESN

is a premium nitrogen product that does

cost more than conventional nitrogen, so

producers need to be able to see value in

the product.”

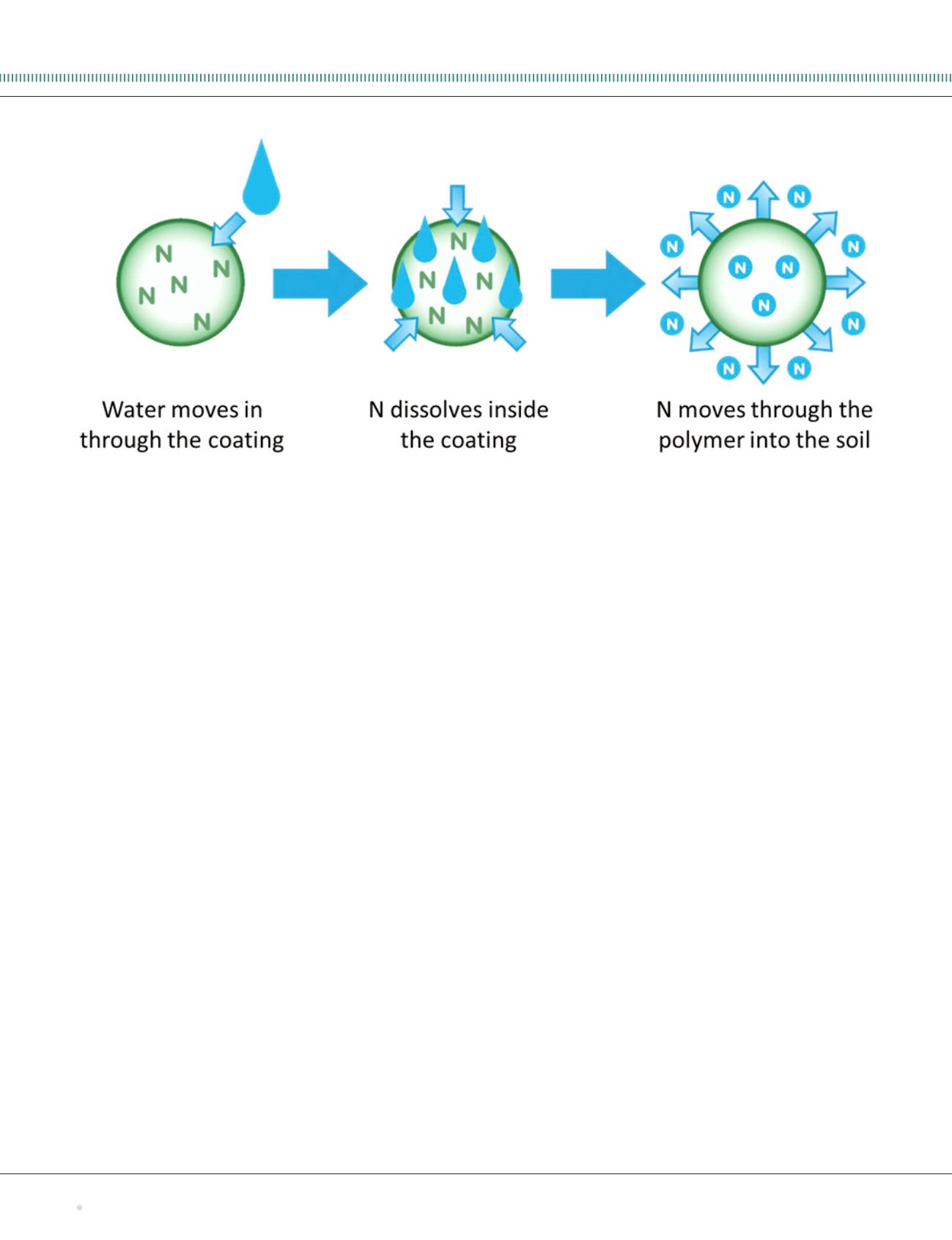

Lawson said ESN is a polymer-coated

urea and can be fall applied and ideally

incorporated, or spring banded right in

the seed row or beside the seed as part

of the fertilizer blend. Once the product

is applied in or on the soil, moisture will

move in through the polymer coating

and dissolve the urea inside. As the soil

warms, the nitrogen—being temperature

sensitive—diffuses out through the

porous polymer membrane. As moisture

levels and soil temperatures change,

nitrogen is gradually released for up to

80 days.

“We are positioning it as a broad-acre

product that can be used with all cereals

and oilseeds including canola and flax,”

he said. “Some producers have used it,

for example, with wheat crops on sandy

soils with the intent of boosting protein

yield. And that does have a fit, but it can

be used with all crops and provide an

economic return.”

Lawson said on-farm trials have

consistently shown every dollar spent on

ESN can produce a $3 net return through

higher yield with canola. In wheat, he

said it similarly produces a 2.5-to-one to

three-to-one return on investment while

protecting against all three nitrogen-loss

mechanisms.

He also points out ESN’s flexibility. If

applied in fall, it won’t release into cold

or frozen ground. If wet soil conditions

prevail, the polymer coating reduces

nitrogen leaching. And under drier

conditions, it conserves nitrogen until

sufficient moisture is available.

Lawson said seed safety is also one of

the benefits of ESN when banded in the

seed row with the fertilizer blend, and

added that ESN can be applied at a rate

up to three times higher than provincial

recommendations for straight urea,

depending on the opener and seeding

tool.

Rory Degenhardt, Dow AgroSciences

research scientist, said nitrogen-

stabilizing products such as eNtrench

and N-Serve have the best fit in areas

where moisture and environmental

conditions are most conducive to

nitrogen loss. “In higher rainfall areas,

leaching and denitrification can be an

issue,” he said. “And it can also be a

concern on irrigated land in the brown

soil zone. Losses can vary from area to

area and from year to year, but losses

in the 10 to 50 per cent range are not

uncommon.”

With the novel micro-encapsulated

formulation of eNtrench, it can be

impregnated on urea or mixed with

UAN or liquid manure. Both eNtrench

and N-Serve products are designed to

do the same thing, which is to slow the

conversion of ammonium nitrogen to the

nitrate form. Product research shows the

use of N-Serve or eNtrench can reduce

leaching losses by 16 per cent, and

denitrification losses—which produce

greenhouse gases—by 51 per cent.

Field-scale trials in 2015 found, on

average, 44 per cent more positive

ammonium was available for the crop

two weeks after emergence when

N-Serve or eNtrench nitrogen stabilizers

were used, compared with unprotected

nitrogen. Keeping more nitrogen in

the positive form protects it from loss.

Yield data showed that crops grown

where nitrogen was protected yielded

higher—3.8 bushels more per acre for

canola and 3.7 bushels more per acre for

spring wheat and durum.

Enhanced efficiency fertilizers (EEF) such as ESN, a polymer-coated urea product, allow nitrogen to diffuse through a porous membrane as temperature andmoisture

conditions change.