BY ANDREA HILDERMAN

On the roadagain

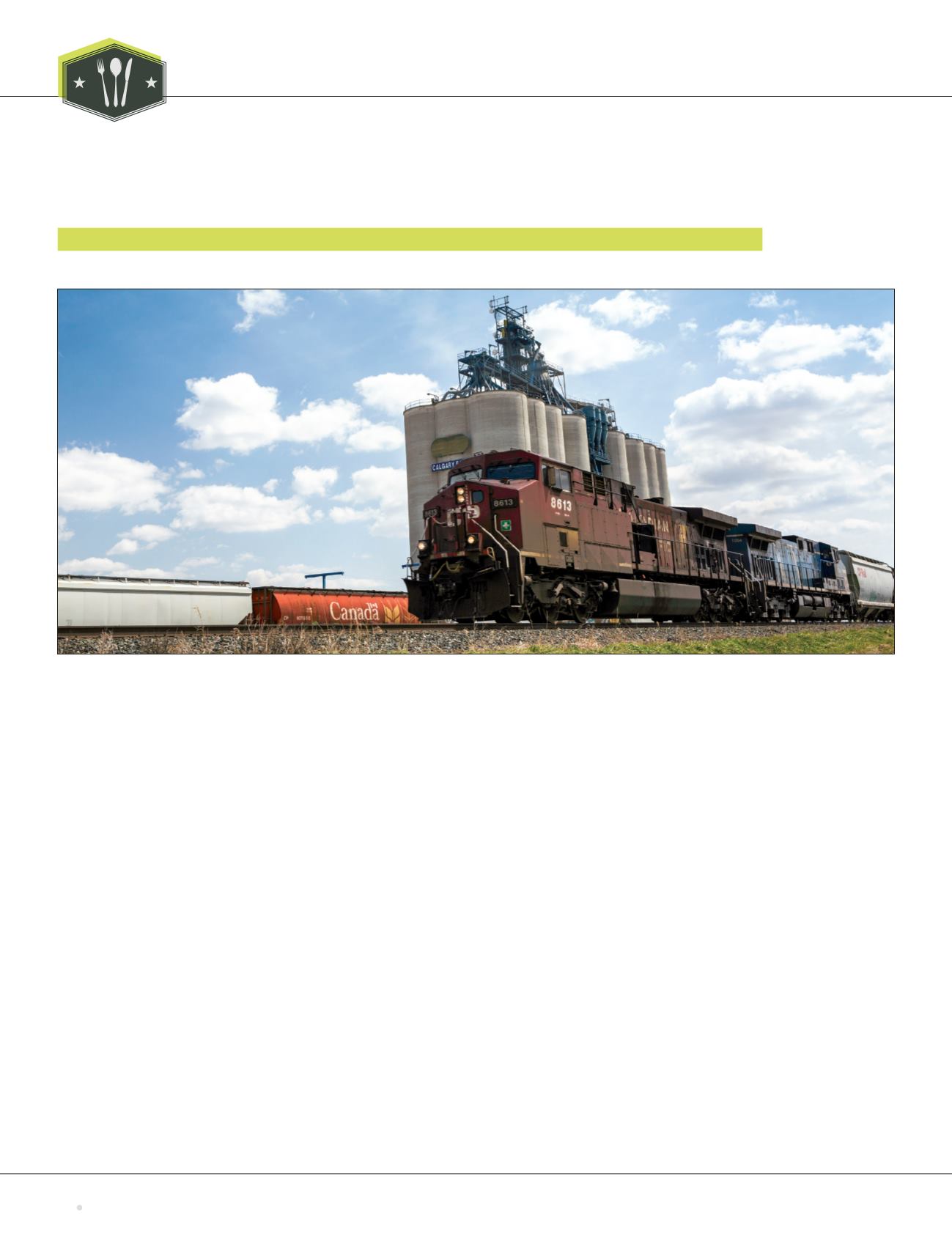

GROWING A SUCCESSFUL CROP IS

the perennial goal of a farmer. However,

that’s just one small step in the bigger

puzzle of turning a profit. Freight costs—

namely trucking and rail—are a fact of life

for farmers, the same way farmers must

always contend with the weather. Farmers

deliver grain to a rural drop-off, then the

grain is moved by rail to a port, where it is

loaded onto a vessel. Where it goes from

there will require a passport.

Without getting the crop to market,

there is no money to pay the bills associ-

ated with preparing the land, growing the

crop, harvesting it and getting it safely

into storage.

Getting the crop “in the bin,” as farmers

say, is really just a starting point. Now

what? Indeed, take another step back.

Moving the crop from the combine in the

field to the grain bin involves a lot of dol-

lars. Farmers have to shoulder significant

risk and debt to move their crops. When

farmers talk about their finances on a

scale of hundreds of thousands of dollars,

it isn’t bragging, it’s just reality.

A combine harvester is emptied many

times as it chews its way through the ripe

crop in the fall. Ideally, this operation

doesn’t stop, day or night, for as long as

conditions are conducive to harvesting

grain that is both ripe and dry enough that

it won’t spoil in the bin.

The combine dumps its load into a grain

cart—a behemoth that can haul up to 20

tonnes or more of grain—pulled by a trac-

tor, which is then driven back to a central

storage area where the grain is transport-

ed into specialized storage bins using a

grain auger. More and more farmers are

using semi-trailers to haul grain from the

field to the yard, and farmers often have

more than one semi in their fleet.

Roger Leroux farms with his brother

Mark and their families nearly 20 kilo-

metres north of St. Paul, AB. Theirs is a

pretty typical Prairie grain farm. Their

business, Leroux Farms Ltd., operates on

about 4,500 acres of farmland. As part of

their mixed grain operation, they also run

a custom feedlot during the winter.

“Everything is a cost for us, for every

farmer,” said Leroux. “Storage in our

main yard is a cost. Hauling the grain

to our storage yard is a cost.” Leroux

and his brother estimate they might

harvest and store in the neighbourhood

of 6,000 tonnes of various grains every

year. “And of course, we have to separate

everything,” he added. “Our barley des-

tined for malting or feed, canola, wheat

and peas have to be kept segregated. And

even if we have different qualities of the

same grain, that has to be kept separate

as well.”

At harvest, the Leroux family hires help

to ensure there are enough hands to run

the combines, move and maintain equip-

ment, haul grain and complete the myriad

Growing a successful crop is only the beginning. Transporting that crop tomarket can be a long and expensive process.

Photos: Michael Interisano

The Food Issue

2016

Grains

West

44

HAULINGGRAIN IS JUST PARTOF THE JOB IF YOUWANT TOBE A FARMER

FARMING

101