Fall

2017

grainswest.com15

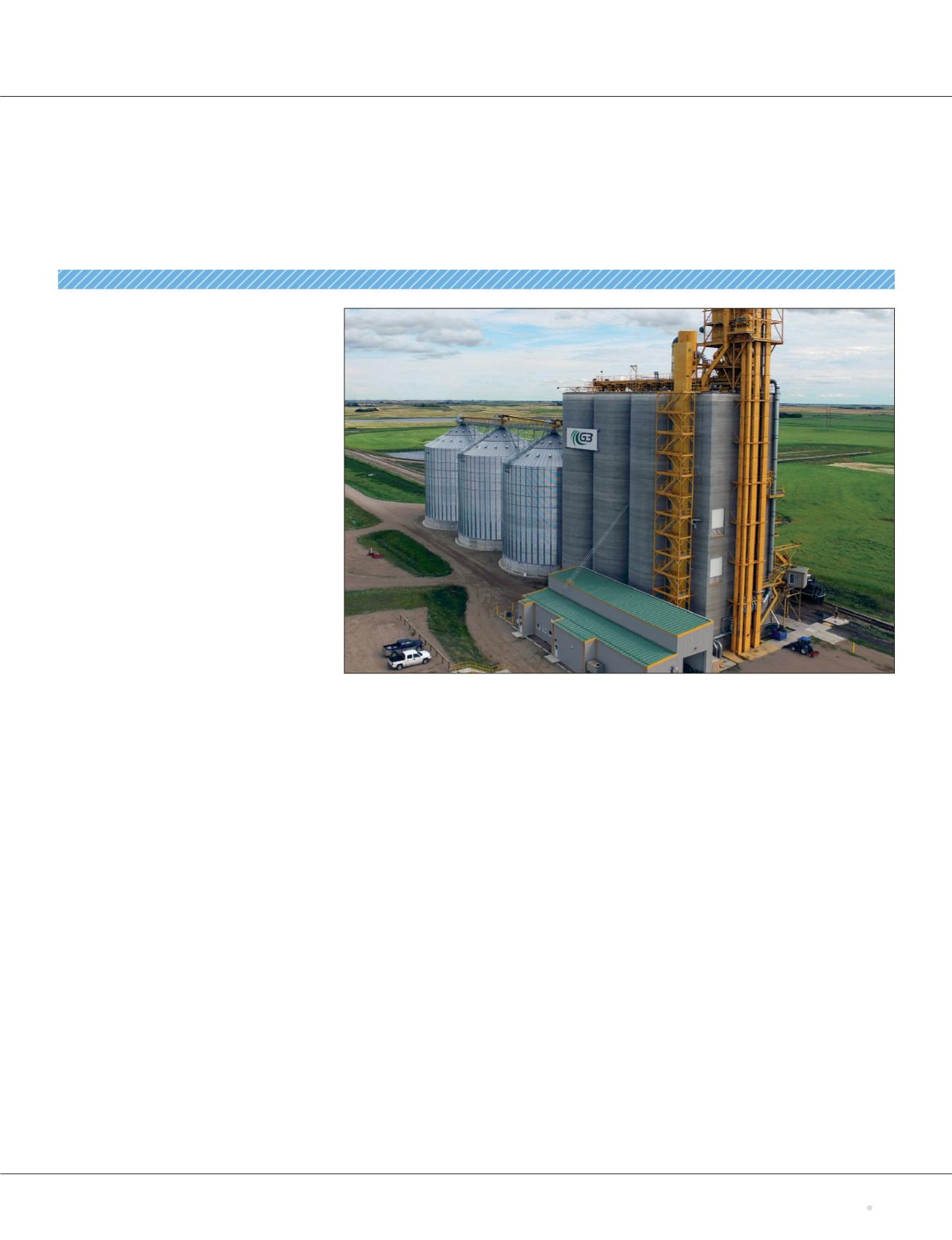

WHENTHEGRAINGETSGOING

LOOP TRACK ELEVATORS PARTOF INCREASEDWESTERNCANADIAN

HANDLINGCAPACITY

Photo:G3CanadaLimited

BY KARIN OLAFSON

OVER THE LAST TWO YEARS, LOOP

track grain elevators have been built across

Canada. These facilities can load and move

grain more efficiently, but they’re just part

of the picture. Much of the efficiency gain

over two decades has occurred at con-

ventional, straight-track facilities, where

improvement may yet occur.

At loop track facilities, locomotives

circle the elevator, receiving grain without

braking. Trains of up to 135 cars are loaded

continuously, and a locomotive’s power

needn’t be turned off. Pickup and delivery

is fast and seamless. Volume moved in-

creases, while time taken decreases.

In addition to building a loop track

facility at Port Metro Vancouver on the

North Shore, G3 Canada Limited is build-

ing such facilities across the Prairies. “We

plan to build another eight high-efficiency,

loop track facilities over the next three

years,” said Karl Gerrand, G3 CEO. “Three

years from now, G3 will have about 25

facilities across Canada.”

G3 plans to handle between 300,000

and 400,000 tonnes per year at each

country facility. Gerrand estimates an

efficiency increase of up to 40 per cent.

GrainsConnect is constructing four

130-car rail loops to more efficiently move

Canadian grain to buyers in China, Japan,

Southeast Asia and the Middle East.

President Warren Stow said two facilities

in Reford and Maymont, SK, are nearing

completion and two in Vegreville and

Huxley, AB, are also in the works.

Paterson Grain also operates one loop

track facility, with another under con-

struction.

Stow and Gerrand said these facilities

are essential for Canadian grain to remain

competitive. “Canada continues to be

one of the leading grain suppliers in the

world,” said Gerrand. “We produce more

grain every year, and our infrastructure

needs to keep up with the growth.”

“In the time that we’ve been monitoring

the grain handling and transportation

system, it’s improved phenomenally,” said

Mark Hemmes, president of Quorum

Corporation, which functions as Cana-

da’s grain monitor. This is indicated by

the shortened time it takes grain to go

through the system. Between 1999 and

2002, the average was 60 to 80 days, but

over the past three years the number has

been consistently in the low 40s. In this

time, average train size increased from 20

to 30 cars per train to around 85.

Hemmes doesn’t doubt loop-track facil-

ities will create huge efficiency gains, but

this is now only theoretical. A closed loop

system such as between individual coalm-

ines and Vancouver and Prince Rupert ter-

minals—all with loop-track facilities—can

work well, said Hemmes. “That’s not the

way the grain industry works.” He noted

more than 380 origins deliver to about 17

terminals. “It’s not going to work the same

way two trips in a row.”

G3 has the only loop-track port facility.

Not yet complete, it will face rail conges-

tion caused by neighbouring elevators,

chemical plants and more.

Of the 200 high-throughput elevators

out there, most feature straight-through

loading configurations and represent huge

sunk assets. As well, construction costs

are high, and large, flat parcels of land

required for loop tracks are scarce. “Loop

tracks are a great concept, but you’re not

going to mothball a bunch of elevators to

do this,” said Hemmes.

While loop tracks become more preva-

lent, straight-loading facilities will create

further efficiency gains. Accommodating

112-car trains, most can be extended to

134 and 136 cars, concluded Hemmes.

Within three years’ time, Grain handler G3 Canada Limited will operate 25 loop-track facilities across Canada,

including this one, located in Colonsay, SK.