Spring

2016

grainswest.com

41

happen when food barley was co-milled with wheat. At that

time, the study looked at 15 per cent food barley and CWRS

wheat. Funding ended, but the idea sat at the back of Sarkar’s

mind as a potential way to improve barley milling.

Then, a er attending a food barley research industry-sharing

event two-and-a-half years ago, there was another mention of

the co-milling potential. As a result, the opportunity opened up

to work with Alberta Barley. This most recent project ran from

April 2014 to March 2015.

The potential of milling hulless barley for flour is multi-levelled.

Hulless barley means there’s no need for pre-processing to

remove hulls, thus eliminating a step for millers.

Garson Law, Alberta Barley’s research manager, pointed out

that eliminating the need to temper the barley prior to milling

makes the job easier for processing.

The fact that there’s less processing creates a flour

considered “whole” by industry, Sopiwnyk said, which is

also an advantage. Research results showed that, with some

baking of the barley/wheat flour, the bread satisfied the Health

Canada nutritional claims for barley beta-glucan. “This will

help (processors) develop more healthy products without the

added costs of new equipment,” she said.

Meeting those health claims is critical in the food industry,

as consumer awareness and interest in functional foods grows.

Health Canada’s health claim states that consuming food

barley can reduce the risk of heart disease and regulate blood

glucose levels.

Law is encouraged by the results and the potential they hold.

“We scratched the surface of what would need to be done.

We’re still deciding where we want to go next with this. A lot of

that has to do with interest from the value chain,” he said.

Locking in that value chain before heading down the path of

production is key, he said, but the research lays the foundation

for future success. “We’ve shown the potential with this

project.”

One challenge that Cigi researchers faced was having

enough sample barley to do a full round of testing, Law said.

However, he acknowledged the difficulty of getting a crop into

the ground that doesn’t yet have an established market.

“It's a chicken-and-egg problem. The farmers are not going

to grow it unless they can see a market, and the processors

aren’t going to commit to products unless they have a steady,

reliable supply,” he said.

For Alberta Barley, it’s all part of building the foundation

in order to realize the potential. The GoBarley campaign,

administered through the Barley Council of Canada, targets

consumers and helps foster interest among the general public.

Law said the commission works in part to create consumer and

food manufacturer awareness of the benefits of consuming

barley products. Still, moving a new product from inception of

an idea to the grocery store shelves requires a concerted effort

by the entire value chain, he said.

“No one group can do everything. The trick is to bring those

entities together,” Law said, and be ready with the products as

consumer interest—and therefore demand—begins to grow.

Alberta Barley creates the platform for discussion between

members of the value chain.

So, is the potential reality of commercialization close enough

for farmers to plant hulless barley this spring for milling flour?

Not quite, Law said. It goes back to the need for more research

into flour mixes and baking in order to get the barley into the

ground. And for that to happen, more hulless barley samples

are needed. That means Alberta Barley is seeking acreage

where samples can be planted.

Although timelines can vary greatly—from a few months

to a dozen years—when all of the players are in place and

motivated, commercialization can happen quickly. Law

referred to one foreign trade mission that arrived in Alberta

with a team made up of the entire value chain. Eighteen

months later, Duga Barley had product on the grocery shelves

in Norway.

“They were all ready to go. They had identified the market

and were willing to work together to develop products that

consumers wanted,” he said.

That’s possible in Canada, too, he added.

“We’ve got all the pieces that one would need to have

success with barley bread and other products. What remains

to be seen is how much consumer interest is out there, and

identifying a food processor to work with. A lot of work is

going into creating the interest.”

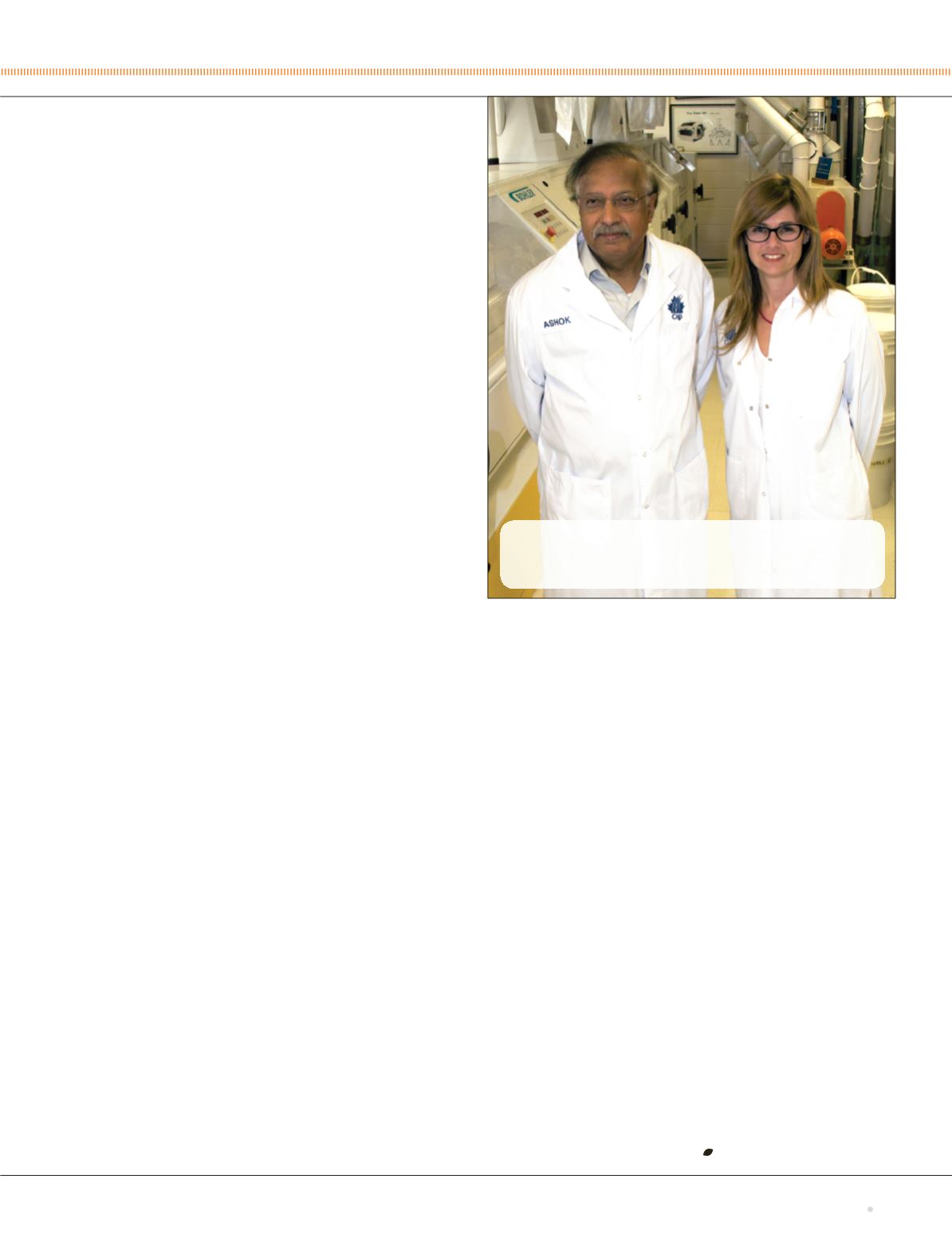

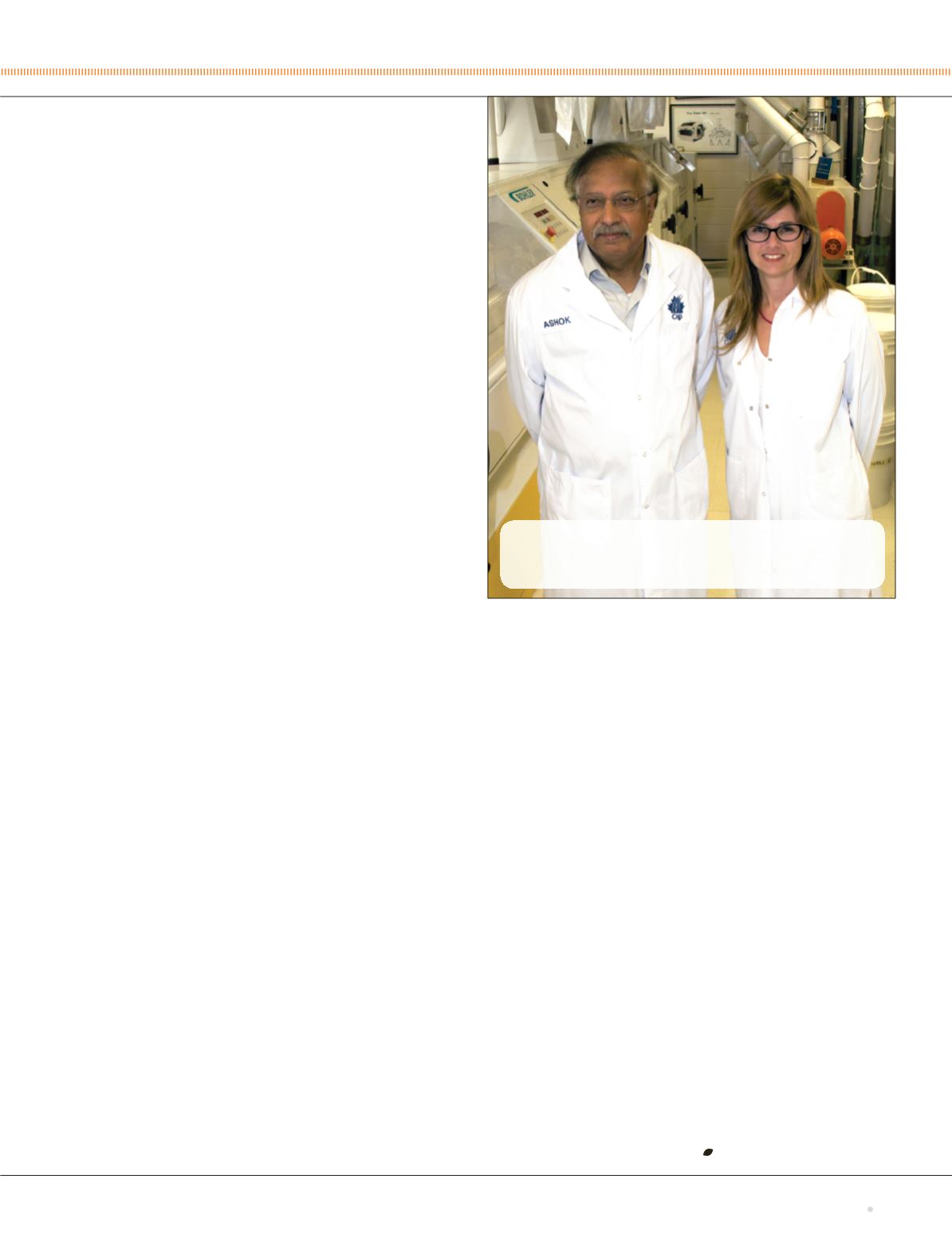

BLENDED FAMILY:

Cigi’s senior advisor in milling technology

Ashok Sarkar (left) and director of grain quality Elaine Sopiwnyk led

the institute’s barley and wheat co-milling project.