Spring

2016

Grains

West

34

out there with growers and still being

evaluated by the brewing industry,”

Beattie said. He pointed to AAC Connect

and CDC Bow as two varieties that show

promise. “From a grower’s point of view,

they offer improved yield potential and

have quite good lodging resistance.

From a malting and brewing point of

view, they offer increased extract and

very low beta-glucan levels.”

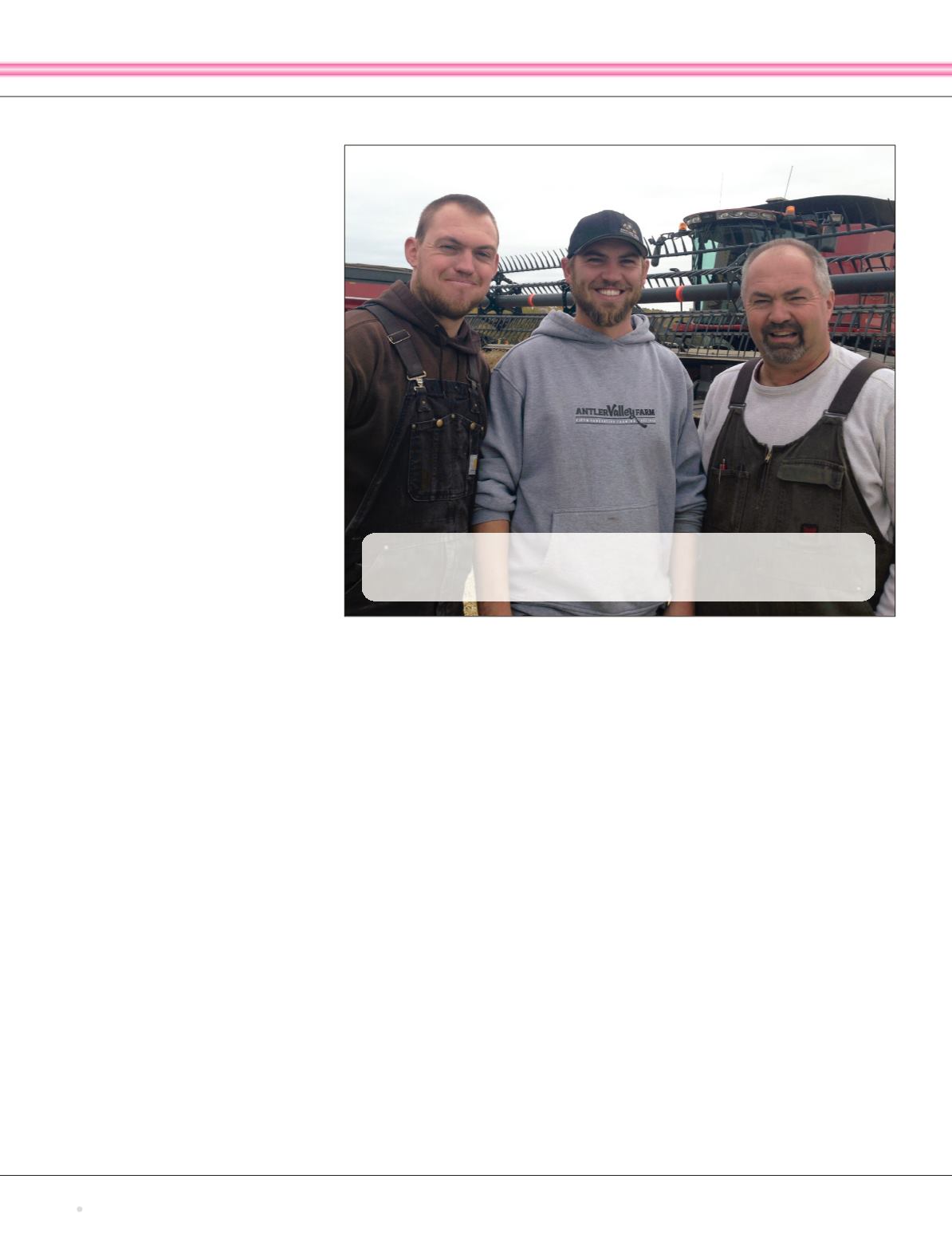

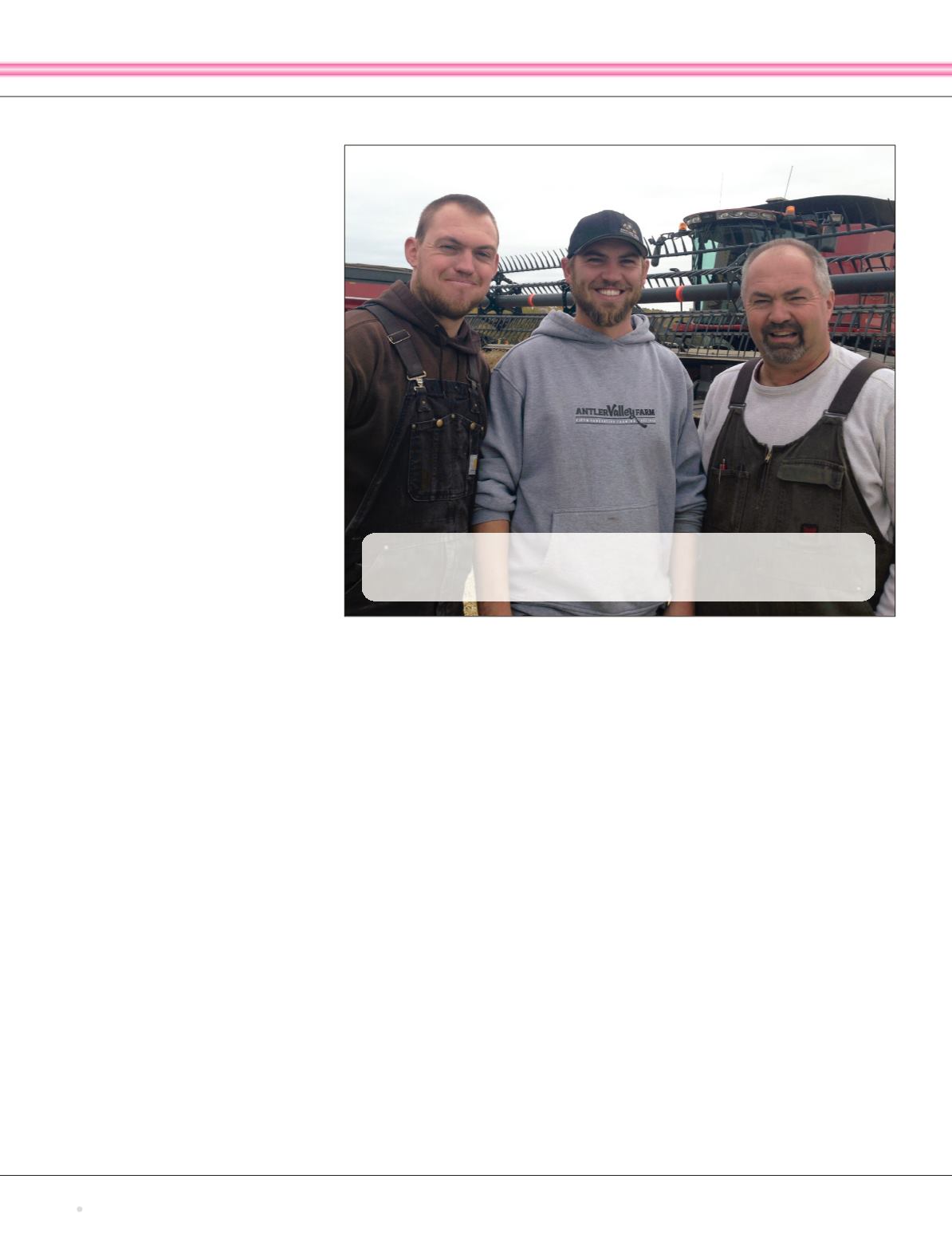

Wade and Scott McAllister at Antler

Valley Farm focus on growing CDC

Copeland. For them, it’s a variety

that balances a relatively high level of

demand from the malt houses with

positive feedback from the craft brewers

they work with. In 2016, they have plans

to seed 20 per cent of their malt acres

in AAC Synergy in response to requests

from craft brewers.

“Working with craft brewers like

Graham at Tool Shed has been a great

experience for our family, as they explain

and show us how different malt barleys

create different products, and [the]

challenges they have to acquire the

finished product that they strive for,”

Wade McAllister said.

Even for barley farmers, making the

connection between what’s in the bin

and what’s in the bottle is a fairly new

concept. That connection is something

that Sherman and the team at Tool Shed

think is important to help cultivate the

stories that make their beer stand out.

“I think about the barley farmers

honing their craft, doing their best work,

then they send their barley off to the malt

house, and what? It’s like sending your

kids off to university and not being able

to see what they become when they

grow up,” Sherman said. “We want them

to know how much pride we take in what

they do. Our beers are the fruits of their

labours.”

It’s an idea that resonates at Antler

Valley Farm. It’s as much about the

personal fulfilment as it is about the

business opportunities.

“Our relationship with the craft brewers

has given us an opportunity to grow

what is needed in the local marketplace,

and we love to grow an excellent-quality

product that will fill that,” McAllister said.

“This also lowers our dependence on

our rail system for export markets, as the

transportation system has been letting

producers down in the past years.”

CRAFT MALT EVOLUTION

Despite the emphasis on the personal

connection that farmers have to craft

brewing, the connection between farmer

and brewer is most often brokered by

one of a few major malting companies.

Collectively, Canadian maltsters buy

approximately 1.1 million tonnes of malt

barley each year. Roughly two-thirds of

the malt they produce goes to export

markets, while domestic brewers use up

the remaining third.

As brewers and consumers seek more

complex flavours in their beers, the

emergence of craft maltsters seems to be

a natural evolution within the industry. At

Red Shed Malting, brothers Matt and Joe

Hamill are leveraging a passion for home

brewing and more than 85 years of family

history in barley growing into a micro-

malting business.

“Red Shed Malting is the missing link

in the chain between the barley grower

and the brewmaster,” Matt Hamill said.

“We will produce a traceable, local and

specialized malt that brewmasters can

use to create beer with consistently more

flavour.”

Once they are operating at full

capacity, Red Shed Malting will produce

about 250 tonnes of malt per year. The

brothers are partnering with their father,

John Hamill, at Hamill Farms to provide

the barley.

“Our farm has been growing malt

barley since 1929, so we’re pretty

experienced at growing and have had

good success at getting it accepted by

the big malt houses,” John Hamill said.

“Canada Malting and Rahr have specific

malts that they want us to grow, and I’m

excited to have more control over the

types of barley we grow here.”

Despite high demand for CDC

Copeland, Hamill prefers to plant AC

Newdale and Bentley—two varieties

known for their performance in the

brewhouse.

FAMILY AFFAIR:

Five generations of McAllister men have been a part of Antler Valley

Farm since it was established in 1890. Currently, it’s operated by brothers Wade (left) and

Scott (centre), and their father, Wayne (right).