GRAIN

SCIENCE

NEWS

Above thegrade

FOR WESTERN CANADIAN GRAIN

producers, the 2016/17 growing season

saw environmental conditions that were

nearly perfect—perfect for a dramatic

increase in

Fusarium graminearum

in their

wheat crops, that is. As a result, the year

revealed several potential drawbacks to

Canada’s current wheat grading system.

Sarah Foster, president of 20/20 Seed

Labs in Nisku, said that beginning in Sep-

tember of last year, her lab began receiv-

ing calls from farmers to complain about

what they perceived as unfair downgrad-

ing and discounting of their grain due to

the current testing processes.

“We heard reports that inspectors were

seeing spores on the crease of the seed

and symptoms of Fusarium on the seed,”

she said. “But when the grain was actually

tested for deoxynivalenol (DON), the next

step of the quality assessment, the DON

had nowhere near the amount of infection

the grader was suggesting there was.”

While minimally toxic to animals in

small amounts, at higher levels DON can

result in reduced feed consumption or

feed refusal. When farmers bring their

grain in to sell at the elevator, DON levels

are estimated through a physical inspec-

tion for Fusarium, where kernels that

appear damaged are counted. In addition,

Falling Number (FN) testing is conducted,

also assessing the grain visually for sprout

damage that can a ect its bread-making

quality. Many farmers who have had

samples downgraded for sprouting have

received independent FN results that

indicate good milling quality.

Foster said there have been com-

plaints about these visual—and therefore

subjective—tests for a number of years,

and more accurate testing methods are

needed on site at the elevators to clear up

MOREOBJECTIVEGRAIN TESTINGANDGRADINGREQUIRED TOKEEP

these kinds of issues and ensure farmers

are paid fairly for the quality of grain they

produce.

“These are general quality standards

where the physical appearance of the grain

is spoiled, but it may not have an e ect on

the final product,” she said. “The Alberta

Wheat Commission (AWC) recently said

‘enough,’ and they are requesting a more

scientific way to establish the grade.”

Kevin Auch, AWC’s chair, strongly

agreed that modernization of Canada’s

current grading system is required to

better meet the demands of international

buyers.

A grain farmer himself, he understands

well the importance of meeting buyer

demands, particularly at the export level.

He estimates that approximately 80 per

cent of the wheat grown on his 5,000-

acre farm near Carmangay ends up in the

export market. Auch said this number was

typical of most Prairie operations, depend-

ing on the year.

“If grain buyers around the world are

buying the product based on certain crite-

ria, and farmers are not paid accordingly,

it makes us farmers less competitive in the

long run,” he said.

In November of last year, AWC called on

the Canadian Grain Commission (CGC)

to implement improved methods of testing

that would ensure farmers maintain their

international competitiveness and receive

fair market price for their grain.

Auch echoed Foster’s suggestion that

the ideal alternative would be to have a

scientifically accurate testing method

available when wheat is delivered to the

elevator that would indicate the actual

DON levels in a sample, and therefore the

fair price for the grain.

“We realize the potential for technolog-

ical constraints in regard to this issue, but

CANADIANGROWERS COMPETITIVE

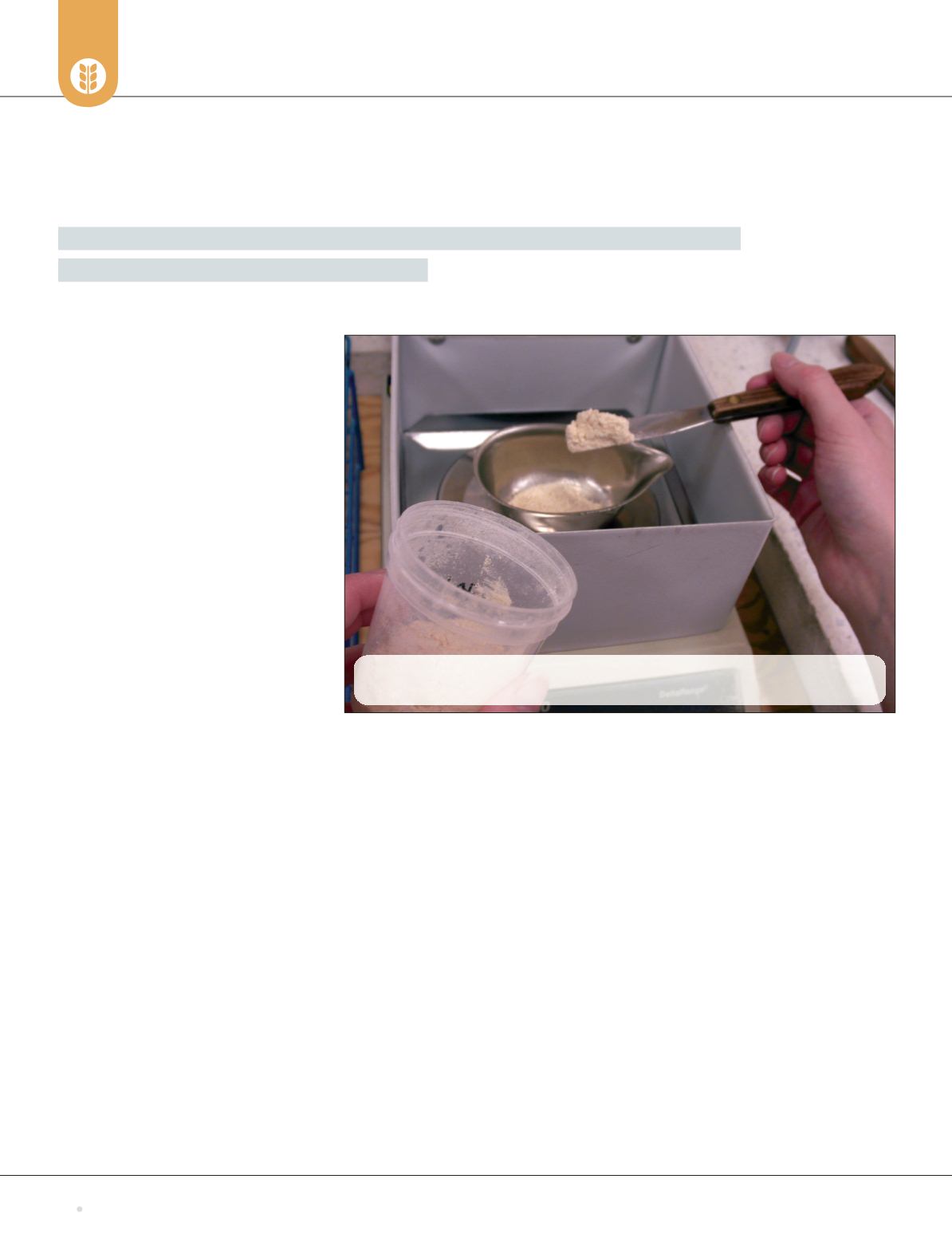

SAMPLING THE SLURRY:

A ground wheat sample is measured before being mixed with water

to form a slurry for Falling Number testing.

Photos:CanadianGrainCommission

Spring

2017

Grains

West

42