TECH

@WORK

Spraysaver

WEED-TARGETING TECHNOLOGY ANOTHER STEP IN

LAST SUMMER, I FOUND MYSELF

transfixed by a video of a new sprayer

technology called WEEDit. The system

has the potential to reduce herbicide use

by 85 per cent, saving farmers money or

making it more cost effective to use

higher-strength products to combat

control-resistant weeds. With the world

closely watching agricultural practices,

WEEDit has the potential to demonstrate

farmers’ commitment to applying the

minimum spray required to maintain the

highest productivity.

Developed and commercialized by

Dutch company Rometron, WEEDit relies

on pulse width modulation technology.

Its sensors, placed at one-metre intervals

along the nozzle boom, focus a red LED

light that pulses 44,000 times per second

on the ground 65 centimetres ahead.

When the light hits green plant material,

it causes the chlorophyll in the leaf to

phosphoresce. This process emits a faint,

near-infrared light that is picked up by the

sensors. A signal is then transmitted to a

solenoid, causing the spray nozzle to open,

precisely targeting the plant. If no further

signal is detected, the nozzle closes after

five nanoseconds.

Each sensor is divided into five channels

that individually survey a 20-centimetre-

wide strip and control one of five spray

nozzles. This ensures that the system

accurately surveys the ground it passes

over. A full 36.5-metre system consists of

36 sensors and 180 spray nozzles.

Importantly, the pressure at each nozzle

remains consistent regardless of speed.

Touted as being able to work effectively at

up to 25 kilometres per hour, the system

doesn’t hinder sprayer efficiency. As well,

the technology works for pre-seeding and

post-harvest burndown, as it will spray

any green material.

Travis Albrecht farms near Schuler, and

was the first owner of a WEEDit system in

Canada. He saw the system in action on

the Facebook page of an Australian farm-

er. Initially developed for hot-water weed

control on Europe’s cobblestone streets,

the system was first used for agricultural

purposes in Australia and South America

before coming to North America. Albrecht

retrofitted his John Deere self-propelled

sprayer and saw dramatic reduction in his

herbicide use in 2017. After harvest, he

loaded his tank with water and glyphosate

to determine how WEEDit product usage

compared to blanket spraying.

“We should’ve been empty at 87 acres,

and we were spraying consistently over

700 acres,” said Albrecht. That’s one-

eighth the amount of chemical used, or

an 87 per cent reduction. On a 2,500-acre

farm, spraying one litre per acre of

glyphosate at $6.50 per litre, that’s a

saving of over $14,000. This might allow

money to be budgeted for a tank mix that

better controls problem weeds such as

glyphosate-resistant kochia or Canada

thistle. Along this line, Albrecht added

Lontrel, a herbicide that normally costs

him $20 per acre, to his tank mix.

Although crop protection products are

fairly inexpensive, Albrecht believes this

will change. “There will be some new

chemicals that they’re going to come out

with, and instead of being $5 to $6 an

acre, it’s going to be $10 or more, which is

going to make this technology even more

valuable.”

Last fall, Albrecht conducted WEEDit

demonstrations using water-sensitive pa-

per to assess spray coverage. The system is

guaranteed to sense weeds as small as one

centimetre square, and Albrecht said even

weeds half that size triggered the nozzles.

As well, the WEEDit monitor allows the

operator to adjust the margin to spray

from 10 to 50 centimetres on either side of

the weed to compensate for wind drift.

Sprayer technology specialist Tom Wolf

attended a demonstration in Saskatch-

ewan and describes the equipment as

“future ready.” “I think we are about to

enter a sensor revolution in ag,” said Wolf.

“Our ability to identify areas that should

be treated in a different way is going to get

easier. A system like [WEEDit] is perfectly

positioned to prepare us for an in-crop,

weed-detecting algorithm.” That is, in fu-

ture, such a system would be able to spray

only the weeds within a standing crop.

Some questions remain as to how the

system would work with residual chem-

istry often used in pre-seeding spray

applications to control weeds that emerge

along with crop seedlings. Spot spraying

would not produce uniform residual activ-

ity, Wolf pointed out. “It leads people to

think about other things like having more

than one tank or having direct injection of

chemical,” he said. “You might have one

mode of action broadcast but have one

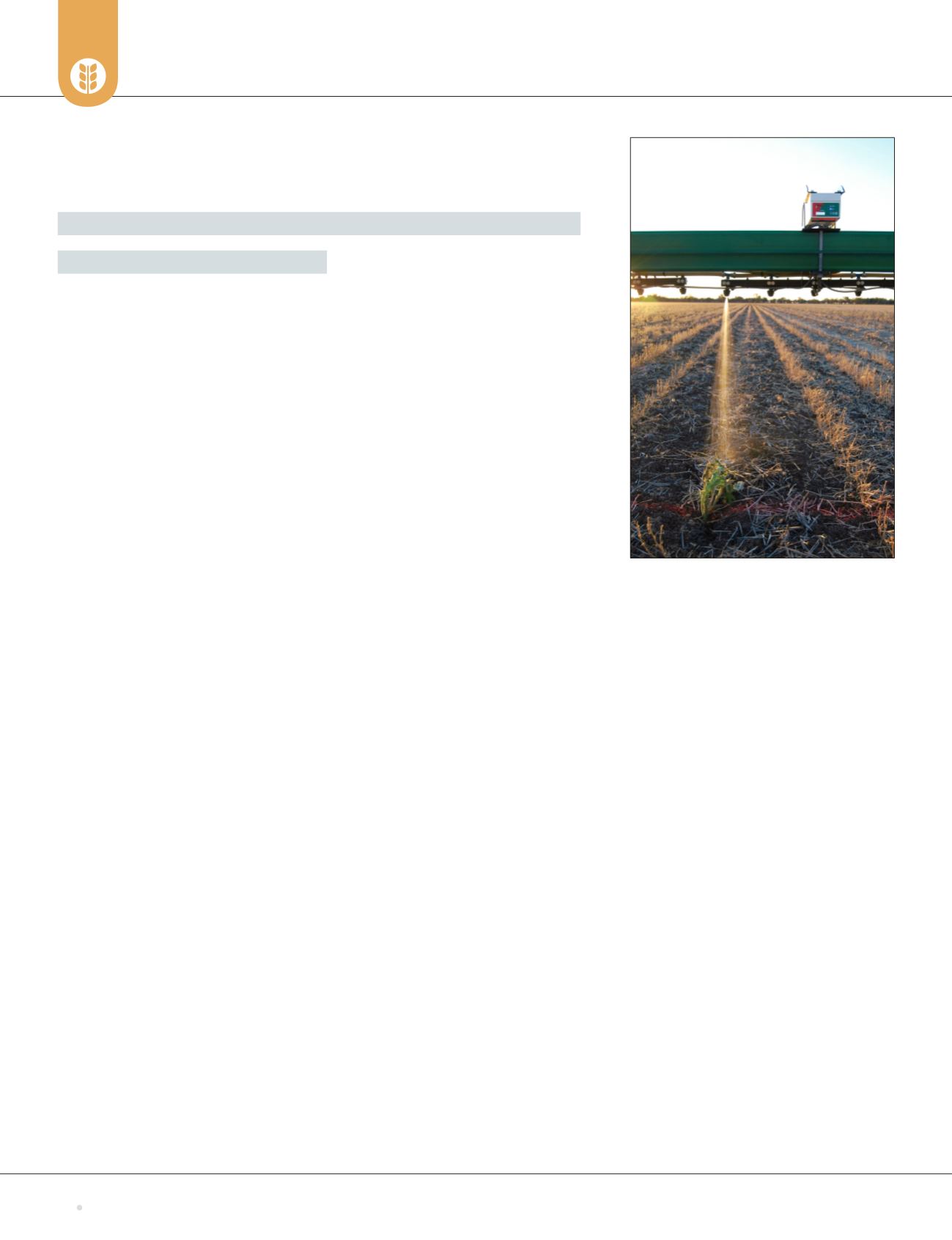

Sensors on theWEEDit nozzle boom trigger spray

nozzles that precisely target green plant material,

decreasing the amount of chemical required for

maximum effect.

Images:WEEDit

THE SENSOR REVOLUTION

Spring

2018

Grains

West

42