were some rejections, but everybody

knew what was going on. It just wasn’t a

great year.

GW:

Is it ever difficult to balance the

interests of farmers with those of

brewers?

KS:

Sometimes, because you do create a

personal relationship. Most times, I feel

even if you can’t take the guy’s barley, he

feels you were actually trying for him.

That’s the benefit to a hands-on relation-

ship, because you can talk to them and

tell them what’s going on. Ten years ago,

that didn’t happen as often. The farmer

just heard his barley was rejected and that

doesn’t go over well.

GW:

Rahr’s Chinook Arch Growers pro-

gram with the Lagunitas Brewing Com-

pany is one of your most well-known

programs. How did it come to be?

KS:

At the end of the Canadian Wheat

Board, Lagunitas wanted to meet some

farmers. When the free market started,

they came up to Canada. I arranged a

meeting and brought five local farmers,

and it was born. I didn’t realize that day

what was happening, I was just told this

brewer wanted to talk to farmers.

Little did I know they were making a

sales pitch to the growers, asking them

to grow under contract. It was the first

contract of its kind, and we were proud to

make it happen. As Lagunitas became a

powerhouse in the craft brewing indus-

try, it was a great synergy because they

needed more barley, so we brought more

accounts on.

We do have other brewers with three-

year contracts, you just don’t hear quite

as much about them. The farmers are

loving it because they’ve got a profitable

price for their barley for the next three

years.

GW:

Can you tell us about Rahr’s

traceability program?

KS:

In 2010, we were the first malt

company in Canada to have one. We

said we want a total trace on the crop

from seeding to harvesting. We wanted

to know all the pesticides and fertilizers

used. We were also trying to establish

best management practices. Why are

certain producers better at growing malt?

We’ve seen things get more uniform and

consistent. We can go to all our brewers

and say, “Hey, we know pretty much right

to the field where your product is coming

from.” That’s powerful stuff.

GW:

What excites you the most about

the future of barley in Alberta?

KS:

Malt barley is really taking hold

as a specialty crop. In the past, we saw

barley acres declining in Canada, and

there has been a lot of doom and gloom

about barley. By capturing that specialty

crop and all the little niches and quirks

of the market, you can be doing these

three-year contracts with craft brewers

and you can be doing one-offs here and

there. There are not many other crops

you can do that with. It took a while to

get moving because barley was not a sexy

crop. Now a lot of farmers will come to

meetings and say “Hey, I’m a malt barley

grower,” and they’re proud of it because

they’re growing a specialty crop. That’s

what I find rewarding.

Winter

2018

Grains

West

18

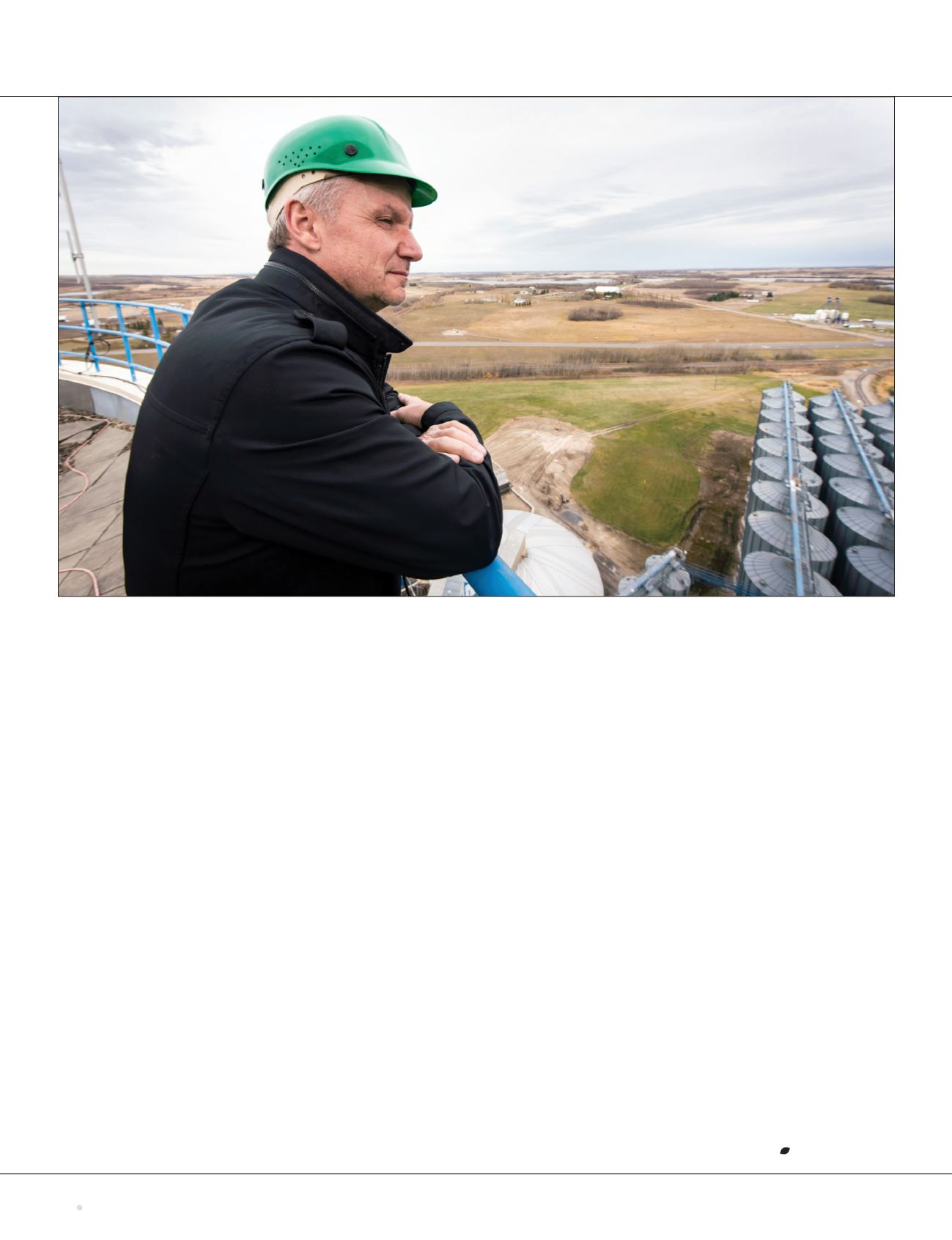

Kevin Sich looks over the expansive Rahr Malting facility in Alix, AB. Its tower malt house has the capacity to process nine million bushels of barley annually.