Basic HTML Version

Photo: iStock Photo

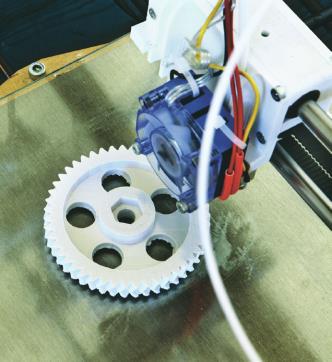

A 3D printed part could save farmers time and money.

Winter

2015

grainswest.com

45

By PETER GREDIG

TECH@

WORK

Anotherprint revolution

Create your partswith3D printing technology

As the price of 3D printing

continues to fall, farmers should start

thinking about what they can and will do

with these devices. It’s not pie in the sky

… it’s here now!

If I’ve said it once, I’ve said it 100 times:

“Can you please drive to the dealership

and pick up a part for me?” A “parts run”

is pretty much a standard practice and an

unavoidable part of agriculture. We use

machinery and it breaks—new parts are

required for repairs.

Huge strides have been made to reduce

the agonizing downtime we experience

while we wait for parts that are not

in stock at the local dealer. Overnight

couriers, mobile parts apps and improved

parts availability have all helped, but the

fact remains that the part is manufac-

tured somewhere, stored in a warehouse

somewhere else, shipped to a local dealer

and then picked up by you or someone you

now owe a favour.

This is about to change, and 3D printers

are the reason.

3D printers have been around for more

than 20 years, but only recently has the

process become economical enough to

be of use to non-commercial users like

you and I. Additive manufacturing is

the technical term for 3D printing. The

most popular application involves using

heated plastic (ABS) that runs through a

nozzle and is secreted in layers to build a

three-dimensional object or, in our world,

a part. It is one of those things that is

difficult to describe, but makes a lot more

sense when you see it in action.

If you do a YouTube search for “3D

printer,” there are some amazing videos

that show how the machines work and

some examples of what can be created.

You will be blown away.

In only a few years, the cost of a 3D

printer has fallen to about $1,000 today

from $5,000 or more. A low-end model

can be had for as little as $500. This tech-

nology will revolutionize light manufac-

turing around the world.

So what’s in it for you? Instead of wait-

ing for a part to be shipped from China,

you will just go online and buy a file that

you download and transfer to a 3D printer.

The printer spits out the part and away

you go.

Plastic is only one material that can be

used. Some 3D printers utilize metal or

super-strong composite materials. Bio-en-

gineers are even using 3D printers to

generate replacement organs and prosthet-

ics for humans. And Chinese technicians

built an entire house using 3D printers to

showcase the technology. It’s even possible

to create food products using 3D printers.

Farm equipment manufacturers are

already using 3D printing technology to

build prototypes before taking a new de-

sign to full production. These prototypes

can be generated at a fraction of the cost

of traditional tooling, so the innovation

process is faster and more economical

than in the past. AGCO Corporation used

this technology to produce new seed

meter designs for its planters. GVL Poly

makes plastic snouts, or dividers, for corn

heads, as well as other harvesting equip-

ment for John Deere, Case IH, AGCO and

others. GVL made a major commitment to

using 3D printing technology to develop

and manufacture the plastic snouts, it has

paid off big time.

Farmers will take 3D printing beyond

just creating replacement parts for equip-

ment. We know farmers are innovative by

nature. The cost of having ideas turned

into prototypes has been a major speed

bump for many would-be entrepreneurial

farmers. The low cost of 3D printing will

stimulate some amazing innovations at

the farm gate.

So you may not be chasing friends and

family to do a parts run for much longer.

The request may soon be, “Hey, can you

print a part for me?” And who knows,

maybe your future field service truck will

have a wireless-enabled 3D printer right in

the field.

Peter Gredig is a corn, soybean and wheat

producer near St. Thomas, ON. He is also

a partner in AgNition Inc., a Guelph-based

mobile development company focused on

building agriculture apps and solutions.